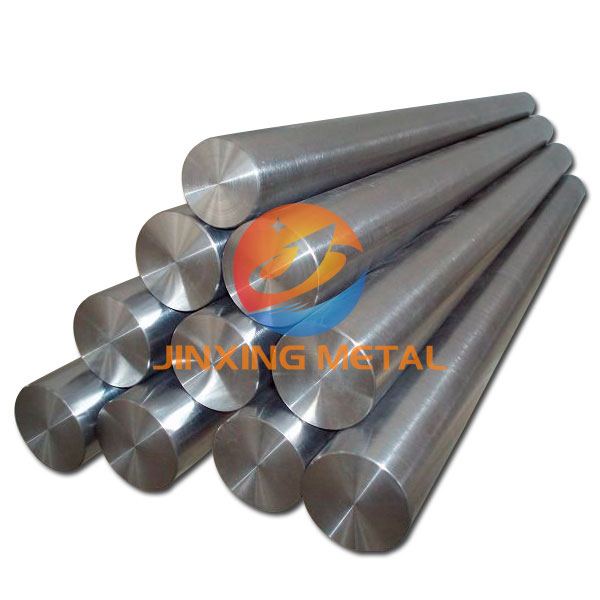

Product Description

Niobium: Gleaming in every color.

Niobium is special because this high level of resistance is achieved at a relatively low weight. We use this material to manufacture coin inserts of all colors, corrosion-resistant evaporation boats for use in coating technology, and dimensionally stable crucibles for diamond growth. Thanks to its high level of biocompatibility, niobium is also used as a material for implants. Thanks to its high transition temperature, niobium is the perfect material for superconducting cables and magnets.

Of coins and diamonds. Applications for niobium.

The applications for which our niobium is used are as diverse as the properties of the material itself. We briefly present two of these below: In actual fact, niobium, like all other metals, is gray. However, by applying a passifying oxide layer, we allow our metal to gleam in a beautiful array of colors. But niobium is not just pretty to look at. Like tantalum, it is resistant against many chemicals and can be easily formed even at low temperatures.

Guaranteed purity.

You can rely on our quality. We use only the purest niobium as our input material. This ensures that you benefit from a very high level of material purity.

Permissible variations in spec.

|

Grade |

Condition |

Diameter |

Length |

Voluntary Standerd |

|

Nb1 Nb2 Nb3 Nb4 |

Cold state(Y) Annealedb(M) |

3.0-6.5 >6.5-10.0 >10-18 |

>500 |

ASTM B392-03 |

|

Thermal processing state(R) Annealed (M) |

>18-25 >25-40 >40-50 >50-65 |

|||

|

FNb1 FNb2 |

Thermal processing state(R) Annealed (M) |

3.5-5.0 >5.0-12 |

>500 >300

|

|

|

NbHf10-1 |

Thermal processing state(R) Annealed (M) |

20-80 |

500-2000 |

Chemical Composition:

|

Designation |

Main Contents |

Impurities maximum |

||||||||||

|

Nb |

Fe |

Si |

Ni |

W |

Mo |

Ti |

Ta |

O |

C |

H |

N |

|

|

Nb1 |

Remainder |

0.004 |

0.003 |

0.002 |

0.004 |

0.004 |

0.002 |

0.07 |

0.015 |

0.004 |

0.0015 |

0.002 |

|

Nb2 |

Remainder |

0.02 |

0.02 |

0.005 |

0.02 |

0.02 |

0.005 |

0.15 |

0.03 |

0.01 |

0.0015 |

0.01 |

Please leave your information to get the latest quotation and product catalogue!