Product Description

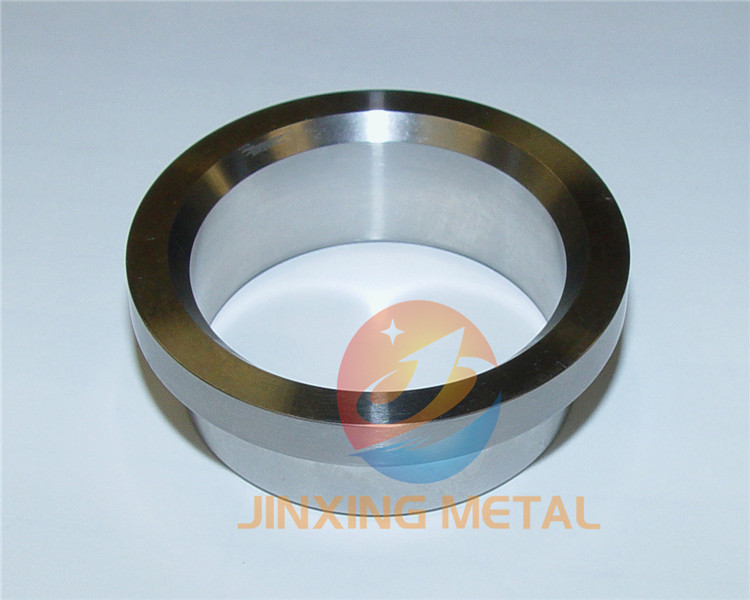

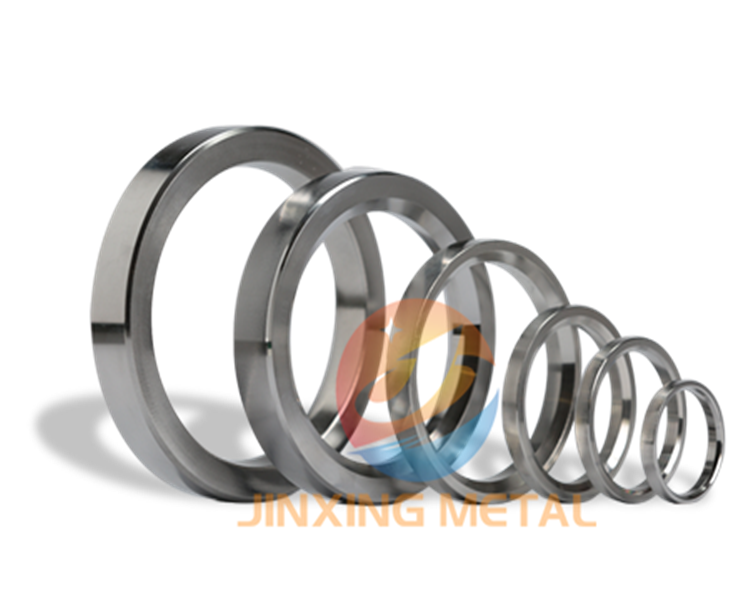

Cobalt Chromium Tungsten Alloy valve seat ring Product Introduction

Cobalt alloy is a range of cobaltchromium alloys designed for wear resistance.It is a completely non-magnetic and corrosion resistant cobalt alloy.There are a number of CoCrWalloys, with various compositions optimised fordifferent uses. Some are formulated to maximize combinations of wear resistance, corrosion resistance, or ability to withstand extreme temperatures.

Cobalt Chromium Tungsten Alloy valve seat ring of Features

1. Heat Resistance, wear resistance, corrosion resistance

2. Made as required dimensions and materials

Material of our Cobalt Chromium Tungsten Alloy valve seat ring

JX-3 equal to the material stellite 3 ( stellite brand belong to Kennametal)

JX-6 equal to the material stellite 6( stellite brand belong to Kennametal)

JX-3 equal to the material stellite 3

JX-6 equal to the material stellite 6

|

Brand |

C |

Mn |

Si |

Cr |

Ni |

Mo |

W |

Co |

Fe |

P |

S |

Density |

Hardness |

|

(g/cm3) |

(HRC) |

||||||||||||

|

JX-3 |

2.0-2.7 |

1 |

1 |

29-33 |

3 |

|

11.14 |

Bal. |

3 |

≤0.03 |

≤0.03 |

8.55 |

51-55 |

|

JX-6 |

0.9-1.4 |

1 |

1.5 |

27-31 |

3 |

1.5 |

3.5-5.5 |

Bal. |

3 |

≤0.03 |

≤0.03 |

8.35 |

38-44 |

|

JX-12 |

1.1-1.7 |

1 |

1 |

28-32 |

3 |

|

7.0-9.5 |

Bal. |

3 |

≤0.03 |

≤0.03 |

8.4 |

44-49 |

|

Material : |

Stellite –Grade 3.6.12 |

|

Process : |

Powder Metallurgy , it is short for PM and investment casting |

|

Hardness: |

38-55 HRC |

|

Density : |

8.4 g/cm ³ |

|

Size : |

Diameter 8-500mm, length 600mm |

|

Properties : |

Wear and corrosion resistance, high temperature resistance |

|

Application : |

as a seal ring |

|

Instructions : |

Drawing made upon customer’s request |

|

Usage : |

sealing parts |

|

Tolerance control : |

turning or grinding surface , tolerance upon drawing |

|

Production lead time |

Samples 10 days , normal order 15-30 days |

|

Production capacity : |

20,000pcs one month. |

|

Package : |

carton or wooden case , pallet for export |

Please leave your information to get the latest quotation and product catalogue!