best price for American standard niobium tube/zirconium tube

best price for American standard niobium tube/zirconium tube

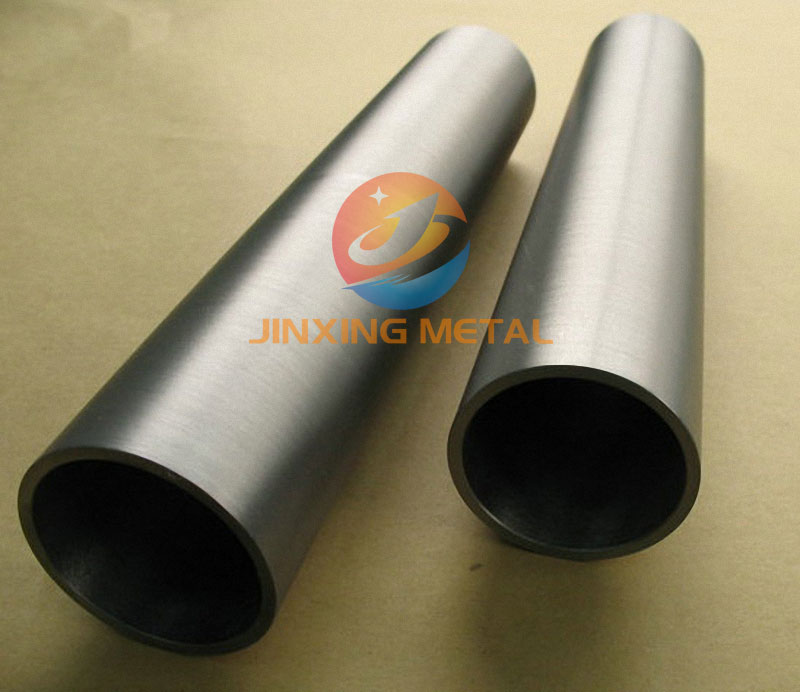

niobium tube/zirconium tube of show

niobium tube/zirconium tube of description

|

Name |

Niobium tube & pipe |

|

Purity |

99.95% min |

|

Grade |

R04210,R04261,Nb1Zr,Nb-Ti, Nb50Ti |

|

Standard |

ASTM B394 |

|

MOQ |

1kg |

|

Delivery Time |

12-15workdays |

|

Market |

Global |

|

Application |

chemistry, electronics, aerospace and other fields |

|

Condition |

Seamless tube: |

|

1. Sintering or forging bar billets |

|

|

2. Perforated tube blank |

|

|

3. Rolled and extruded into tubes |

|

|

4. Capillary rolling mill |

|

|

Welded pipe: Sheet/strip – rolled welding molding |

|

|

Size |

Wall thickness:>1mm, OD(outer diameter) 30mm-650mm |

|

Lehgth:30-1000mm |

Chemistry of niobium tube/zirconium tube

|

Chemistry % |

||||||||||||||

|

Designation |

Chief component |

Impurities less than |

||||||||||||

|

Nb |

Fe |

Si |

Ni |

W |

Mo |

Ti |

Ta |

O |

C |

H |

N |

|

||

|

Nb1 |

Remainder |

0.004 |

0.002 |

0.002 |

0.004 |

0.004 |

0.002 |

0.07 |

0.015 |

0.005 |

0.0015 |

0.003 |

|

|

|

Nb2 |

Remainder |

0.02 |

0.02 |

0.005 |

0.02 |

0.02 |

0.005 |

0.15 |

0.03 |

0.01 |

0.0015 |

0.01 |

|

|

|

Special requirements to be agreed on by the supplier and buyer of negotiations

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Table 2. Mechanical requirements (annealed condition)

|

Grade |

Tensile strength δbpsi (MPa), ≥ |

Yield strength δ0.2, psi (MPa),≥ |

Elongation in 1"/2" gage length, %, ≥ |

|

RO4200-1 RO4210-2 |

18000 (125) |

12000 (85) |

25

|

7. Application:

Ta & Nb products are widely used for electronics,high temperature using parts,reaction containers,ect.