Product Description

Stellite alloy castings and forgings:

Meet the harsh conditions of high temperature, wear and corrosion

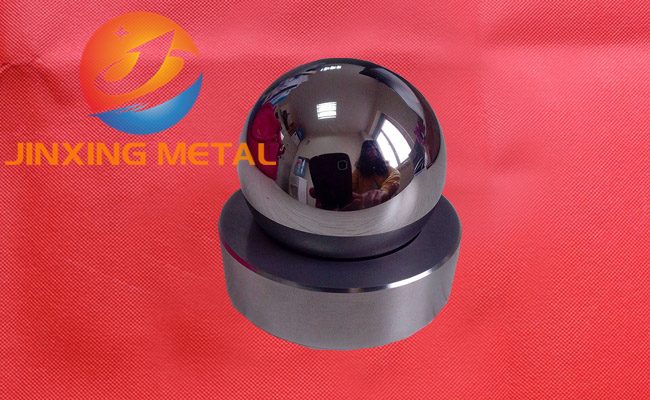

Cobalt Chrome Alloy Ball Valve Seats:Cobalt-chromium-tungsten and cobalt-chromium-molybdenum alloys are classified into heat-resistant and wear-resistant cobalt alloys, high-temperature resistant cobalt alloys, and wear-resistant and aqueous corrosion-resistant cobalt alloys according to their resistance to heat, abrasion and corrosion.

Description of Cobalt Chrome Alloy Ball Valve Seats

1. Valve balls and valve seats are widely used in oil fields.

2. Valve Ball and Seat performance directly affects the use effect and service life of the sucker rod pumps.

3. Each ball-and-seat combination is vacuum tested to ensure a perfect seal is obtained in all positions of contact

Forged stellite6B and stellite6K alloy. Hardness HRC40 and HRC45, improved plasticity due to forging, toughness and impact resistance. Elongation rate of more than 5% and 2%, used in aerospace, chemical, instrumentation, injection molding machinery, molds, molten metal and other fields of valves, valve seats, bearings, sinking rolls, guide rolls, sleeves; stamping extrusion hot forging die , sawtooth, screw push rod, screw, screw, chemical fiber cutting knife, thermocouple protection tube; automotive exhaust valve, steel industry hot processing tooling; and 3D printing cobalt chrome material powder tire frame.

Performance comparison of Cobalt Chrome Alloy Ball Valve Seats

Resistance to cold and heat fatigue, cavitation resistance, low expansion, and dimensional stability are common characteristics of cobalt-based alloys. On this basis, the performance of the commonly used heat-resistant and wear-resistant stellite alloys is as follows:

stellite6B, 6K: heat and wear resistance, impact resistance;

Stellite703: heat and wear resistant, with corrosion resistance;

T-400: heat and wear resistance, higher heat hardness;

HAYNES556: Sulfur-containing environment, the effect is better than nickel-based and iron-based alloys.

Common Stellite alloy hardness index:

Forging stellite 6B, 6K: hardness 40HRC and 45HRC;

Casting stellite 703 and T-400: hardness is 55HRC;

Cast stellite 20: cast cobalt alloy of hardness HRC50;

Forging SC50: Forged cobalt alloy of HRC50.

Heat resistant and wear resistant cobalt alloy

Commonly used stellite alloy application

High temperature resistant cobalt alloy and corrosion resistant cobalt alloy

JINXING METAL丨 focuses on cobalt-based alloys

Overall large deformation forged cobalt alloy (CoCrW, cobalt chromium tungsten)

.

Please leave your information to get the latest quotation and product catalogue!