Product Description

Copper Tungsten Bar Stock

Copper Tungsten Bar Stock composite material is a combination of tungsten and copper. The manufacturing process is as follows: press the refractory metal, sinter the pressed compact at a high temperature, and infiltrate it with copper. All this is done under very closely controlled conditions. The result is a relatively hard material with superior arc and wear resistance, high physical Properties: at elevated temperatures, and good electrical and thermal conductivity.

|

Item Name |

Stock electrode material W-cu Alloy w90cu10 tungsten copper bar rod price |

|

Material |

tungsten copper alloy, copper tungsten alloy |

|

Dimensions |

as request, All parts will be machined as customer's request or drawing. |

|

Density |

11.85-16.75g/cm3 |

|

Grade |

W60Cu40, W65Cu35, W70Cu30, W75Cu25, W80Cu20, W85Cu15, W90Cu10 |

|

Application |

EDM&ECM electrodes, Machining other parts |

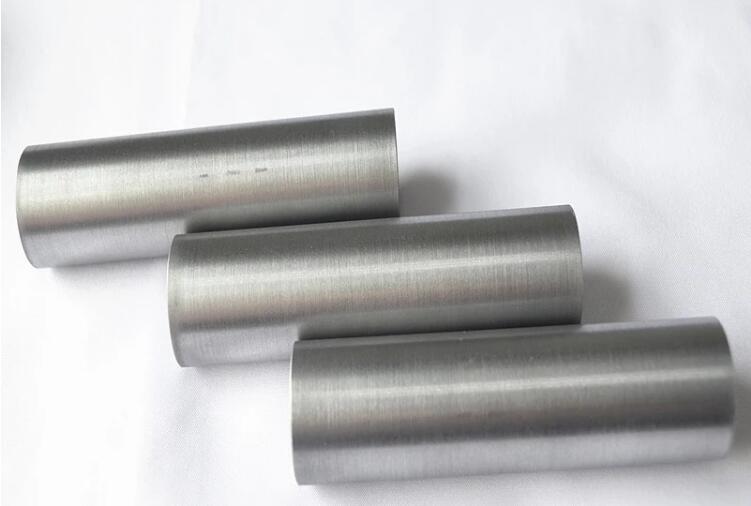

Copper Tungsten Bar Stock Picture:

Copper Tungsten Bar Stock Application

(1).Copper tungsten alloy is used when a product or part needs to have a high heat resistance, low thermal expansion and high electrical or thermal conductivity.

(2)/Tungsten copper alloy is used to make engines and electrical devices. It is also used in the fields of aviation and spaceflight. Electrodes, refractory parts, heat sinks, rocket parts and electrical contacts are all made out of WCu alloy.

(3).The alloy is also made into sheet metal, tubing and plate metal. WCu alloy is used to make contacts for both high and low voltage electrical devices, and for high speed steel devices and switches.

(4).The Spark Erosion (EDM) process calls for copper tungsten. Usually this process is used with graphite, but tungsten has a high melting point.

Please leave your information to get the latest quotation and product catalogue!