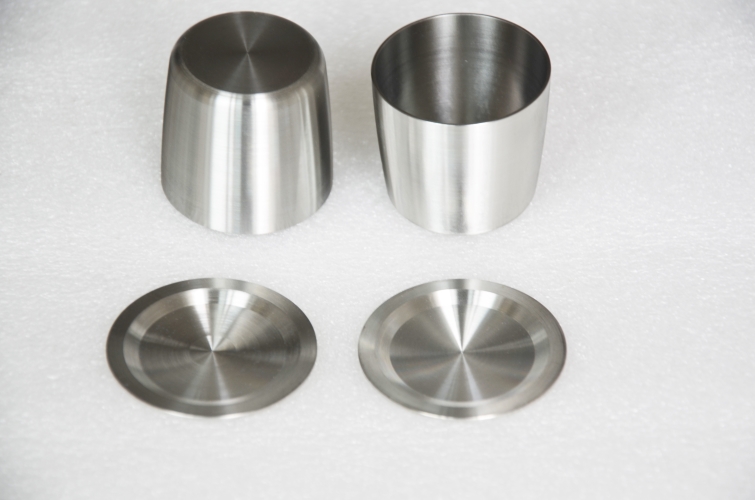

High Purity Zirconium 702 Crucible

High Purity Zirconium 702 Crucible Description

Zirconium has a very small neutron absorption cross-section and a relatively high melting point, making it a good material for nuclear power rods. High Purity Zirconium 702 Crucible is usually made through a series of processes such as injection molding, rolling, powder pressing, sintering, cutting and polishing. It has high melting point, strong thermal conductivity, high purity, corrosion resistance, good high temperature stability, and Wear, thermal shock resistance, creep resistance, long service life and other excellent properties. High Purity Zirconium 702 Crucible can be divided into forging crucibles, machined crucibles, welding crucibles, and stamping crucibles according to different processing. It is widely used in high-temperature smelting, solid-phase reaction, alloy smelting, catalyst research, ceramic sintering, sample preparation and other fields.

High Purity Zirconium 702 Crucible Specifications:

|

Grade |

Zr702 |

|

Purity |

≥99.5% |

|

Volume |

10-200ml and Customized |

|

Thickness |

0.5-20mm |

|

Diameter |

30-150mm |

|

Melting point |

1852℃ |

|

Density |

6.51g/com3 |

|

Surface |

Polishing,Alkali Cleaning,Grinding,Chemical Cleaning,Black Oxide, etc. |

|

Standard |

ASTMB551,ASME,GB |

|

Certification |

ISO9001 |

High Purity Zirconium 702 Crucible Pictures