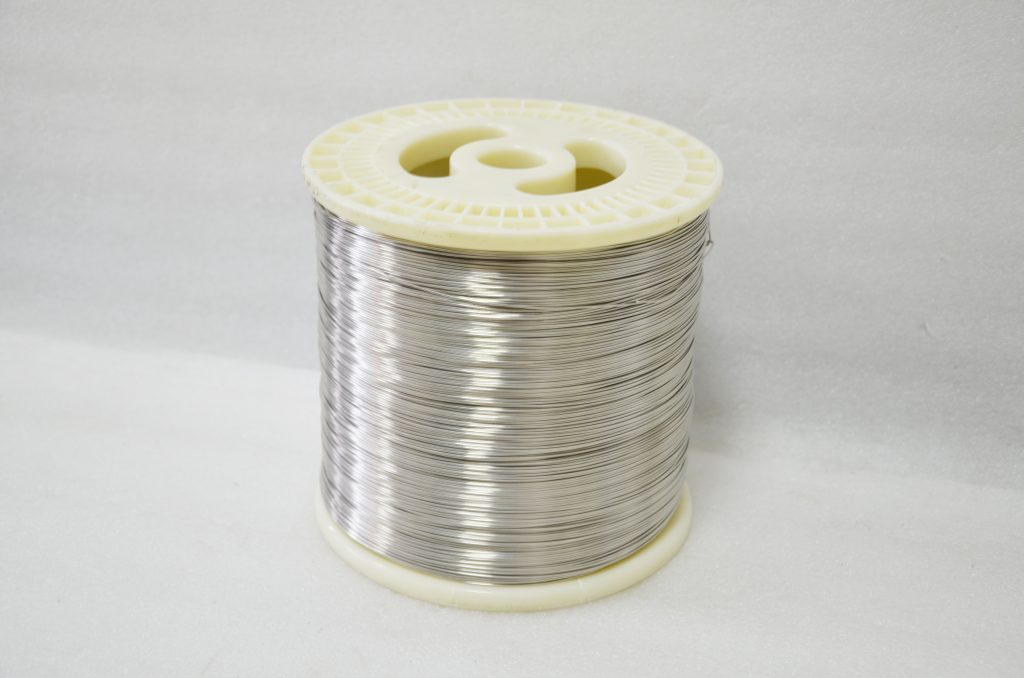

High Purity Nickel Electrode Wire

High Purity Nickel Electrode Wire Description

Nickel has outstanding mechanical strength and ductility, which allows it to be stretched into very fine, high-purity nickel filaments. High Purity Nickel Electrode Wire With super good electrical conductivity and thermal conductivity, low resistivity, high strength, excellent low temperature resistance, good weldability, appropriate line expansion coefficient, good weldability, anti-static and radiation prevention, corrosion resistance, high temperature strength and long life and other characteristics. In particular, the nickel 200 can be subjected to various cold processes, such as stretching and rotation.

High Purity Nickel Electrode Wire Can be applied in a variety of welding fields and EDM, help to improve the stability and reliability of precision welding and processing, and prolong the service life of machine tool equipment. High Purity Nickel Electrode Wire Is an important structural material in vacuum electronic devices. It can not only be used as a guide wire lead in the light bulb, but also suitable for radio, electric light source, mechanical manufacturing and chemical industry.

High Purity Nickel Electrode Wire Specifications:

|

Grade |

N4,N6 |

|

Purity |

Ni:≥95% |

|

Technique |

Straightening,Cold Rolled,Hot Rolled,Rolling,Stretching,Annealing |

|

Diameter |

0.8-10mm |

|

Length |

100-6000mm |

|

Density |

8.9g/cm3 |

|

Melting Point |

1453°C |

|

Surface |

Smooth,Polished,Enamel,Bare,Ceramic,Plated |

|

Standard |

ASTM B865,ASTM B 163,GB |

|

Certification |

ISO9001:2008 |

High Purity Nickel Electrode Wire Pictures: