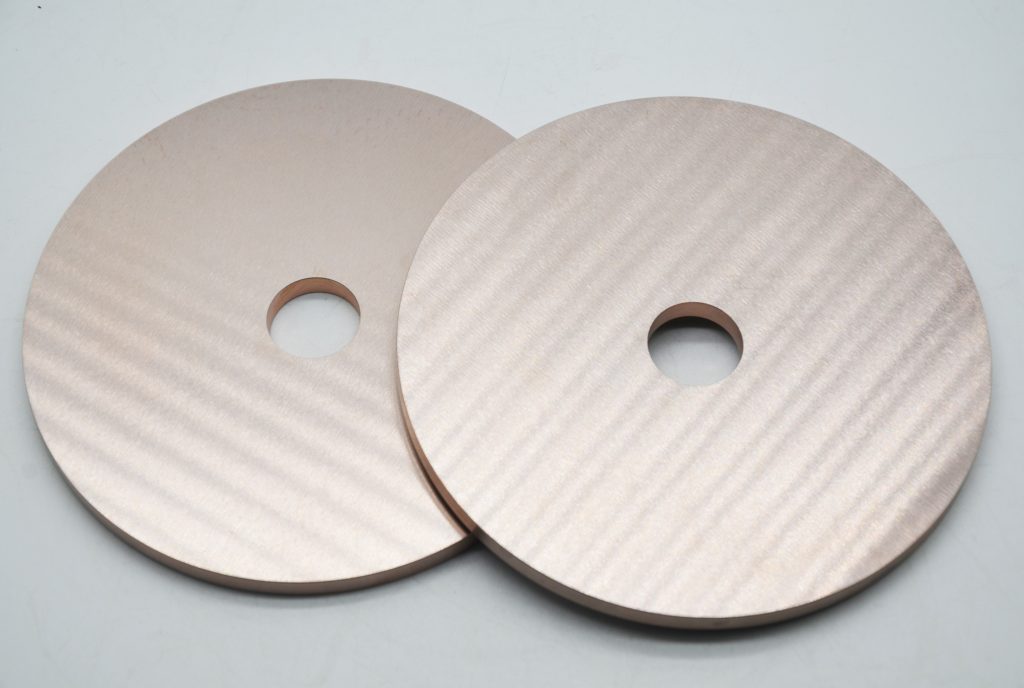

WCu Tungsten Copper Welding Seam Wheel

WCu Tungsten Copper Welding Seam Wheel Description

Seam welding is a resistance welding processing method, in which the weldment is assembled into a butt or lap joint and placed between two roller electrodes. While the rollers are being pressed and rotated continuously or intermittently, electric current is supplied continuously or intermittently to form a continuous weld seam. WCu Tungsten Copper Welding Seam Wheel is the most commonly used resistance welding electrode material, which is generally made of high-performance tungsten copper alloy by powder metallurgy process. It is widely used in oil drum, radiator, aircraft and automobile fuel tank, engine, rocket, missile, and other thin-sheet welding of sealing containers, as well as surface repair processing of PCD tools.

As a composite material of tungsten and copper, WCu Tungsten Copper Welding Seam Wheel has the characteristics of high melting point of tungsten, high heat resistance of copper, low expansion, high purity, good plasticity, strong welding performance, high tool sharpness, stable internal structure organization, good high-temperature resistance, high thermal and electrical conductivity coefficient, and long service life, etc. It can weld higher quality and precision weld seams than other high-purity electrodes, and also improves the processing efficiency of welding technology.

WCu Tungsten Copper Welding Seam Wheel Specifications:

|

Grade |

W75Cu25,W70Cu30,W60Cu40,W90Cu10 |

|

Technique |

Sintering,Annealing,Rolling,HIP,Machining,Injection Molding process |

|

Outer Diameter |

25-175mm |

|

Thickness |

5-10mm |

|

Hardness |

85-100HRB |

|

Density |

14.1-15.35g/cm3 |

|

Surface |

Polished,Bright,Chemical Cleaning,etc. |

|

Standard |

ASTM B702,GB,JIS |

|

Certification |

ISO9001 |

WCu Welding Seam Wheel Picture