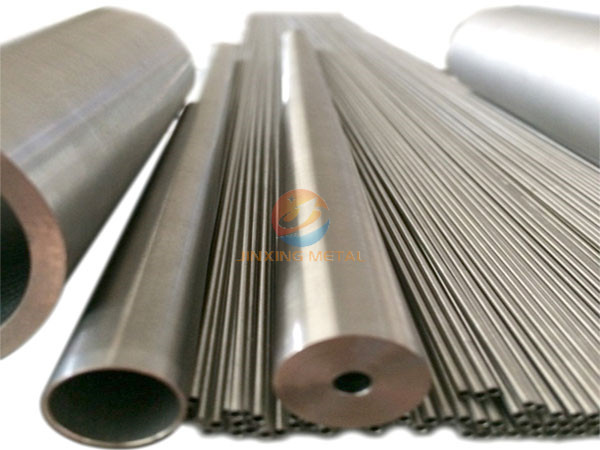

custom made High quality copper tungsten alloy w75cu25 tube

custom made High quality copper tungsten alloy w75cu25 tube

They use the excellent metal characteristics of the high pure tungsten powder and the plasticity and high conductivity of the high pure copper powder to produce composite materials with static pressure molding, high temperature sintering and the the solution process of the copper infiltration technology. These materials have some advantages: the arc ablation resistance, good thermal conductivity, and small thermal expansion, not soften in high temperature, softening, high strength, high density, high hardness etc. Tungsten copper tubes are widely used in machinery, electronics, and aviation, aerospace, military and other fields.

Chemical Composition

|

Class |

Chemical Composition(Wt%) |

Density |

Hardness |

Resistance rate |

IACS |

Bending strength |

||

|

Cu |

Total Additives≤ |

W |

g/cm3≥ |

kgf/mm4≥ |

um.cm≤ |

%≥ |

MPa≥ |

|

|

W93Cu07 |

7±1.0 |

0.5 |

balance |

17.5 |

270 |

7.2 |

26 |

1190 |

|

W90Cu10 |

10±2.0 |

0.5 |

balance |

16.75 |

260 |

6.5 |

27 |

1160 |

|

W85Cu15 |

15±2.0 |

0.5 |

balance |

15.90 |

240 |

5.7 |

30 |

1080 |

|

W80Cu20 |

20±2.0 |

0.5 |

balance |

15.15 |

220 |

5.0 |

34 |

980 |

|

W75Cu25 |

25±2.0 |

0.5 |

balance |

14.50 |

195 |

4.5 |

38 |

885 |

|

W70Cu30 |

30±2.0 |

0.5 |

balance |

13.80 |

175 |

4.1 |

42 |

790 |

|

W65Cu45 |

0.545±2.0 |

0.5 |

balance |

13.30 |

155 |

3.9 |

44 |

650 |

|

W60Cu40 |

40±2.0 |

0.5 |

balance |

12.75 |

140 |

3.7 |

47 |

600 |

|

W55Cu45 |

45±2.0 |

0.5 |

balance |

12.30 |

125 |

3.5 |

49 |

565 |

|

W50Cu50 |

50±2.0 |

0.5 |

balance |

11.85 |

115 |

3.2 |

54 |

534 |

.