grade 1 f67 pure titanium welding wire for medical

grade1 f67 pure titanium welding wire for medical

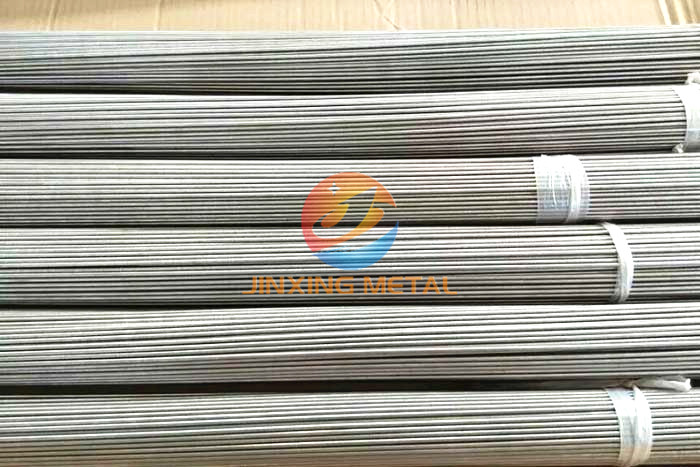

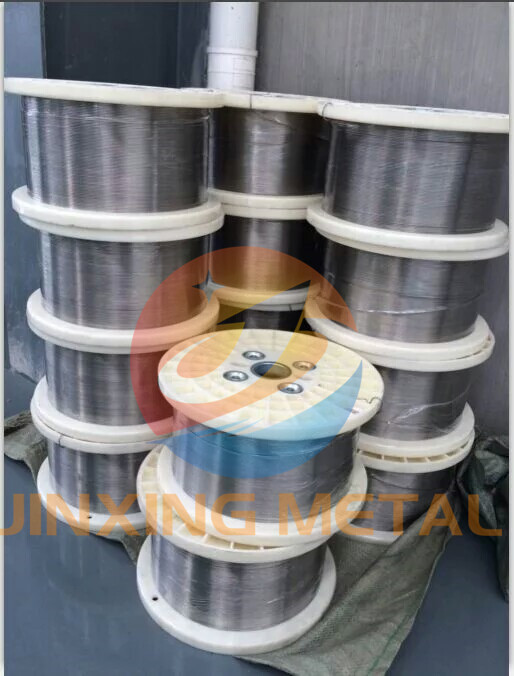

Description of titanium welding wire

Titanium Grade 1-4 is pure Titanium, the other grades are alloys. Pure Titanium is used due to its high corrosion resistance, the alloys because of the extremely high strength to weight ratio.

l Grade 1. Pure Titanium, relatively low strength and high ductility.

l Grade 2. The pure titanium most used. The best combination of strength, ductility and weldability.

l Grade 3. High strength Titanium, used for Matrix-plates in shell and tube heat exchangers.

l Grade 5. The most manufactured titanium alloy. Exceedingly high strength. High heat resistance.

l Grade 7. Superior corrosion resistance in reducing and oxidizing environments.

|

Product name |

Titanium wire |

|

Standard |

AWS A5.16,ASTM B863,ASTM F136,ASTM F67 etc. |

|

Material |

Pure Titanium:Gr1,Gr2,Gr3,Gr4 Titanium alloy: Gr5,Gr7,Gr9,Gr12 |

|

Diameter |

0.1-7.0mm |

|

Length |

Coil wire :according to weight Straight wire:1000,2000,3000mm or as customer's request |

|

Product situation |

Cold rolled(Y)~Hot rolled(R)~Annealed (M)~Solid Status |

titanium welding wire of Chemical requirements(wt%)

|

ASTM |

Fe max |

O max |

N max |

C max |

H max |

Pd |

Al |

Bal |

|

Grade 1 |

0.20 |

0.18 |

0.03 |

0.08 |

0.015 |

– |

– |

Ti |

|

Grade 2 |

0.30 |

0.25 |

0.03 |

0.08 |

0.015 |

– |

– |

Ti |

|

Grade 4 |

0.50 |

0.40 |

0.05 |

0.08 |

0.015 |

– |

– |

Ti |

|

Grade 5 |

0.40 |

0.20 |

0.05 |

0.08 |

0.015 |

– |

5.5-6.75 |

Ti |

|

Grade 7 |

0.30 |

0.25 |

0.03 |

0.08 |

0.015 |

0,12-0.25 |

– |

Ti |

|

Grade 9 |

0.25 |

0.15 |

0.03 |

0.08 |

0.015 |

– |

2,5-3,50 |

Ti |

|

Grade 12 |

0.30 |

0.25 |

0.03 |

0.08 |

0.015 |

– |

– |

Ti |

titanium welding wire of Tensile requirements

|

grade |

Tensile strength(min) |

Yeild strength(min) |

Elongation(%) |

||

|

ksi |

MPa |

ksi |

MPa |

||

|

1 |

35 |

240 |

20 |

138 |

24 |

|

2 |

50 |

345 |

40 |

275 |

20 |

|

4 |

80 |

550 |

70 |

483 |

15 |

|

5 |

130 |

895 |

120 |

828 |

10 |

|

7 |

50 |

345 |

40 |

275 |

20 |

|

9 |

90 |

620 |

70 |

483 |

15 |

|

12 |

70 |

483 |

50 |

345 |

18 |

titanium welding wire of Feature:

• Low Density and High Strength

• Excellent Corrosion Resistance

• Good resistance to effect of heat

• Excellent Bearing to cryogenic property

• Nonmagnetic and Non-toxic