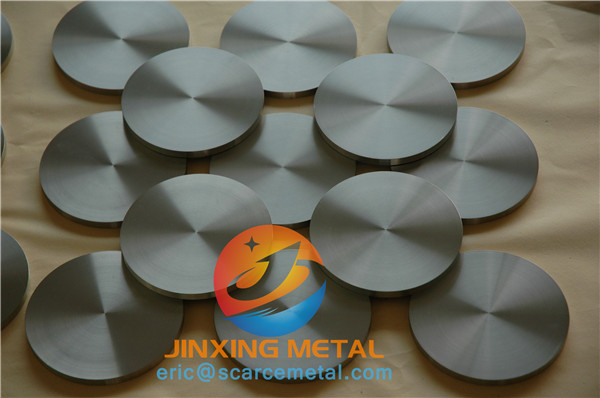

High density 99.95% Mo molybdenum sputtering target

Product Description

99.95% Pure Mo Molybdenum Plate Mo Sputtering Target

Molybdenum is a silvery-grey metal with a Mohs hardness of 5.5. It has a melting point of 2,623 °C (4,753 °F); of the naturally occurring elements, only tantalum, osmium, rhenium, tungsten, and carbon have higher melting points. Weak oxidation of molybdenum starts at 300 °C (572 °F). It has one of the lowest coefficients of thermal expansion among commercially used metals. The tensile strength of molybdenum wires increases about 3 times, from about 10 to 30 GPa, when their diameter decreases from ~50–100 nm to 10 nm.

|

Item Name |

Pure molybdenum sputtering target Pure Mo Sputtering Target |

|

Purity |

99.95% |

|

Shape |

Flat/rotary target, according to your request |

|

Available size |

Round: dia 25~550mm,Thickness:3~30mm Rectangular: Length up to 2000mm Customization is available |

|

Certificates |

ISO9001:2015, SGS, The third test report |

|

Technics |

Hot Iisostatic Pressing, Powder Metallurgy, Patented thermo-mechanical process |

|

Application |

Widely used in coating processing industries A: Solar Photovoltaic Application. B: Electronic and Semiconductor Application. C: Decoration and Coating Application. etc. |

|

Advantages |

Microstructure: Uniform equiaxed fine grain, consistent microstructure, average grain size <100μm |

|

Detailed information |

Molybdenum is silver-white metal, hard and tough. Metal molybdenum is widely used in electronic devices such as tubes, transistors, and rectifiers. Molybdenum oxide and molybdate are excellent catalyst in chemical and petroleum industries. Molybdenum disulfide is an important lubricant for the aerospace and mechanical industrial sector.

Pure molybdenum wire is used for high temperature electric furnaces, electrical discharge machining and wire – cutting; Molybdenum slice is used to make radio equipment and X-ray equipment; Molybdenum is high- temperature and ablation resistant, mainly used for artillery bore, rocket nozzle, manufacturing light bulb tungsten support. Adding molybdenum in alloy steel can increase the elastic limit, corrosion resistance and maintain permanent magnetic etc. Molybdenum in also widely used as substrates of different membrane surface in thin-film solar and other coating industry. |

Other Metal Targets

|

Formula |

Name |

Purity |

Formula |

Name |

Purity |

|

Al |

Aluminum Target |

5N-5N5 |

Nb |

Niobium Target |

3N5-4N |

|

B |

Boron Target |

3N |

Ni |

Nickel Target |

3N5-5N |

|

Bi |

Bismuth Target |

4N-5N |

NiCr |

Nickel Chromium |

3N 3N5 |

|

Ca |

Calcium Target |

2N5 |

Pb |

Plumbum Target |

5N |

|

Cd |

Cadmium Target |

4N |

Sb |

Antimony Target |

4N |

|

Co |

Cobalt Target |

3N5 |

Se |

Selenium Target |

4N |

|

Cr |

Chromium Target |

2N5-3N5 |

Si |

Silicon Target |

5N |

|

CrAl |

Chromium Aluminum |

3N |

Sn |

Tin Target |

4N |

|

Cu |

Copper Target |

4N-6N |

Ta |

Tantalum Target |

3N5-4N |

|

Fe |

Iron Target |

3N5 |

Te |

Tellurium Target |

4N |

|

Ge |

Germanium Target |

5N |

Ti |

Titanium Target |

2N5-5N |

|

Hf |

Hafnium Target |

3N5 |

TiAl |

Titanium Aluminum |

3N |

|

In |

Indium Target |

4N5 |

V |

Vanadium Target |

3N |

|

Li |

Lithium Target |

3N |

W |

Tungsten Target |

3N5-5N |

|

Mg |

Magnesium Target |

3N5-4N |

WTi |

Tungsten Titanium |

3N-4N |

|

Mn |

Manganese Target |

3N |

Zn |

Zinc Target |

4N5 |

|

Mo |

Molybdenum Target |

3N5-4N |

Zr |

Zirconium Target |

2N5-3N5 |