High Quality Mo-La rod Molybdenum Bar Molybdenum threaded rod Price

High Quality Mo-La rod Molybdenum Bar Molybdenum threaded rod Price

Molybdenum Bar of Product Description

Quick Details:

1.Density: 10.2 g/cm3

2.Standard: ASTM B386

3.Processing:Rolling, Forging, Sintering

4.Surface:polishing/ground, caustic washing

5.Feature:Uniform grain with densified microstructure ensures longer use time.High special strenghth,high melt point,Excellent corrosive resistance,good thermal resistance.Professional after-sales service

6.Application: Molybdenum plate are widely used in the construction of furnace tooling and parts and as a feed stock for the fabrication of parts for the electronics and semiconductor industries.

Molybdenum Bar of Manufacturing process:

Spin satin Molybdenum strip – electric furnace heating – spin satin open billet – electric furnace heating – spin satin – molybdenum rod / molybdenum rod

Hole rolling:Molybdenum strip – rolling billet – electric furnace heating – three-roll mill – molybdenum rod / rod

Type and specification:

Item Diameter Length Delivery Status

High purity molybdenum rods 3.0-100mm ≤2000mm Forged sintered polished alkali wash

High temperature molybdenum rods 3.0-100mm ≤2000mm Forged sintered polished alkali wash

TZM rods 3.0-100mm ≤2000mm Forged sintered polished alkali wash

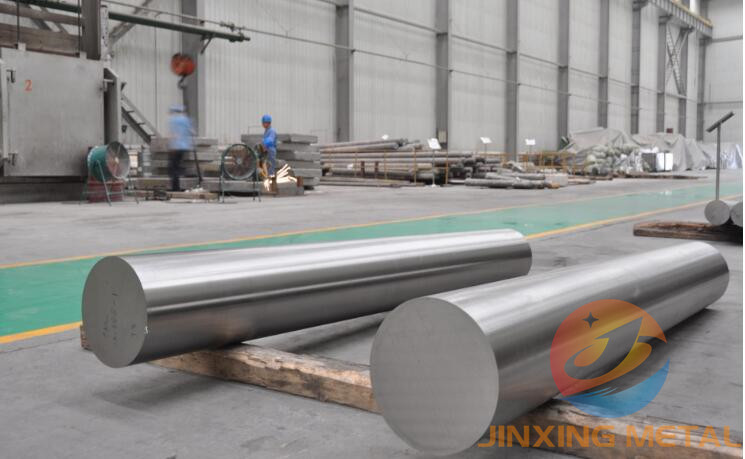

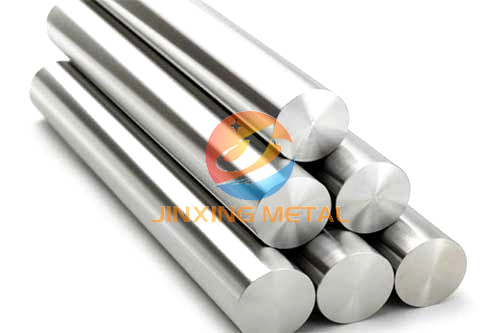

Molybdenum Bar of Products Show

|

Molybdenum products |

Molybdenum plate/sheet/foil (min 0.05mm); |

|

Molybdenum alloy |

MoLa alloy, TZM alloy |

|

Tungsten products |

Tungsten plate/sheet/foil (min 0.05mm) |

|

Tungsten alloy |

WCu alloy,WLa,WNiFe and WNiCu heavy alloy. |