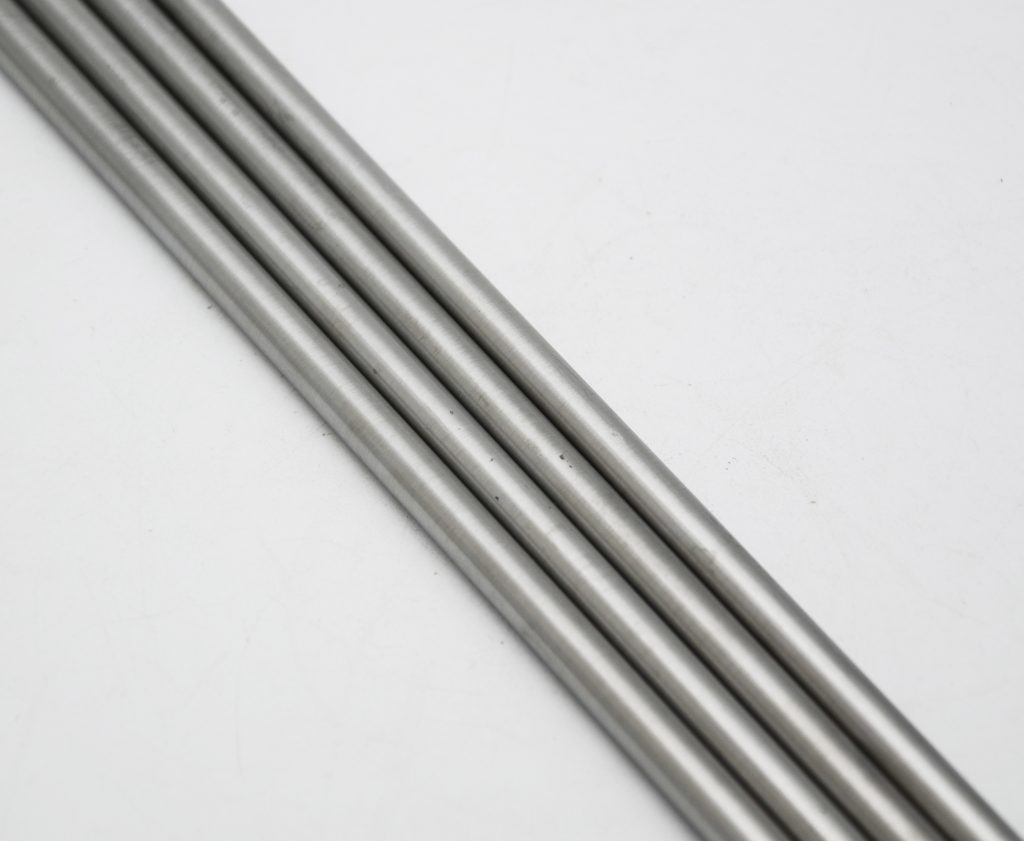

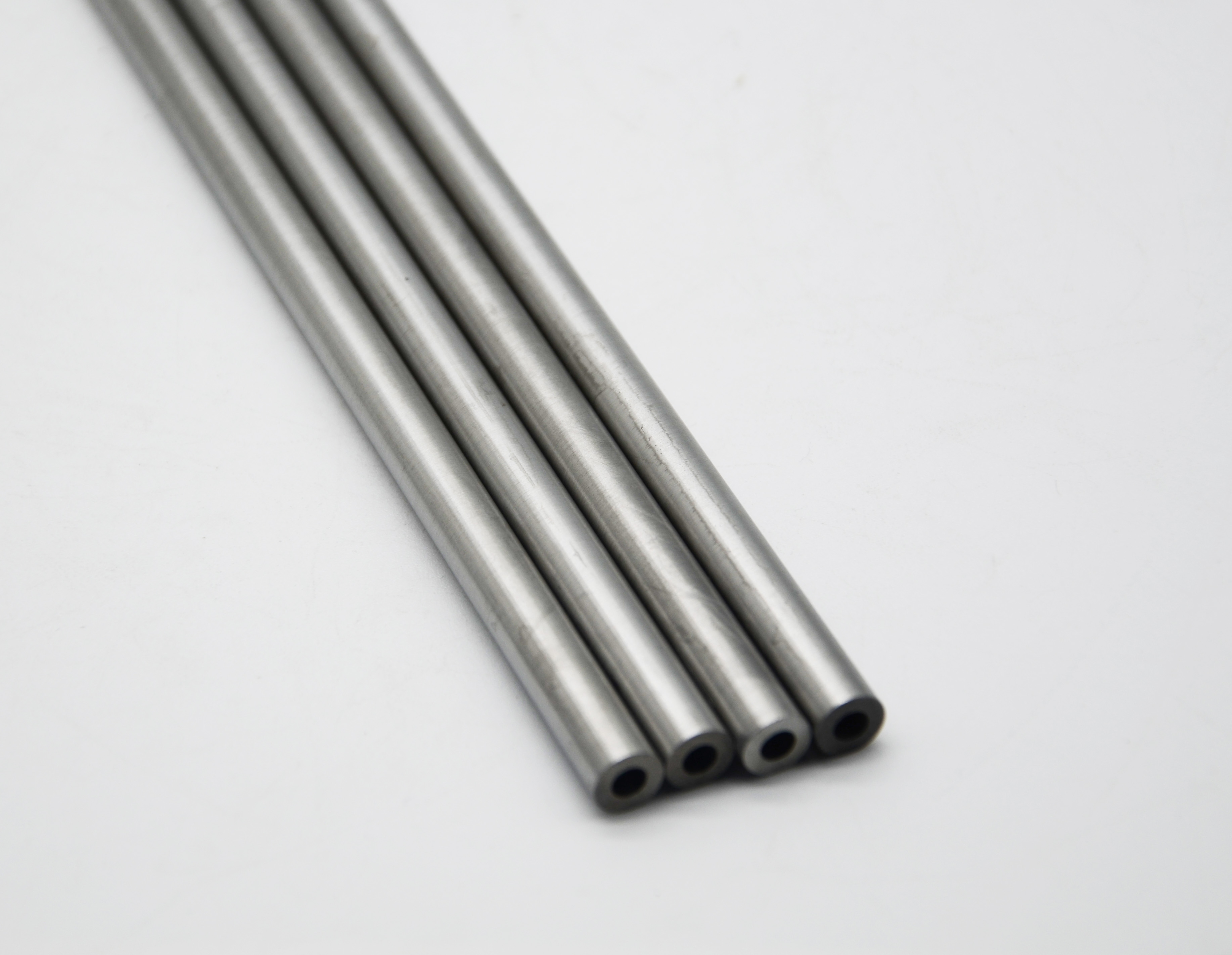

Molybdenum Tube & TZM Tube

Molybdenum Tube & TZM Tube Description

Molybdenum Tube is mainly a tubular material made of pure molybdenum or molybdenum alloy processed by powder metallurgy. It is the most commonly used key component in aerospace, defense industry, high-temperature equipment, electronics and semiconductor processes. According to different processing techniques, it can also be divided into: sintered tube, welded tube or drawn tube, etc. It has a series of advantages such as high melting point, excellent mechanical strength, high temperature resistance, corrosion resistance, oxidation resistance, wear resistance, good high temperature stability, environmental protection and durability, low cost, and good conductivity.

TZM molybdenum alloy is mainly composed of molybdenum, zirconium and titanium, among which zirconium and titanium can improve the high temperature strength and corrosion resistance of molybdenum alloy.

TZM Tube is mainly used in manufacturing fields under harsh environments such as high temperature, high pressure, and strong corrosive media, such as aviation, aerospace, chemical industry, electronics, and nuclear industry.

Molybdenum Tube & TZM Tube are often used to make thermocouple protection tubes, high-temperature furnace components, electronic devices, resistance welding electrodes, and can also be used as metal coatings or rotating targets in the field of solar energy. The prepared molybdenum film can effectively collect and transmit electrons, reduce internal resistance, and thus improve the conversion efficiency of solar cells.

Specifications:

|

Grade |

Mo1,Mo2,TZM(Ti:0.4-0.55%,Zr:0.06-0.12%,C:0.01-0.04%) |

|

Purity |

≥99.95% |

|

Diameter |

3-500mm |

|

Length |

100-2000mm |

|

Wall Thickness |

2-150mm |

|

Density |

10.2g/cm3 |

|

Tensile Strength |

800-890MPa |

|

Melting Point |

2610℃ |

|

Shape |

Round |

|

Surface |

Polished,Sintered,Forged,Grinding |

|

Standard |

ASTM,GB,AISI |

|

Certification |

ISO9001 |

Molybdenum Tube & TZM Tube Pictures