Product Description

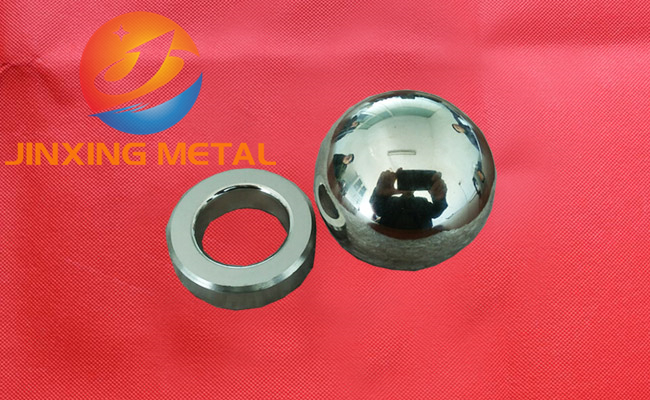

API Standard Cobalt Tungsten Chromium Alloy Valve Seats For Oil Well Pump Valve Corrosion Resistance

Cobalt Tungsten Chromium Alloy Valve ball and seat are very important parts of oil-well pump , they always show up together and cooperate very good , no better material can replace them now . The valve balls are made of Stellite 20 and stellite seat are made of stellite 3 . They are a good team to resist the wear and corrosion issue in oil and gas pimping process .

Details of our Cobalt Chromium Tungsten Alloy Valve Seats and ball?

JX-3 equal to the material stellite 3 ( stellite brand belong to Kennametal)

JX-6 equal to the material stellite 6( stellite brand belong to Kennametal)

JX-3 equal to the material stellite 3

JX-6 equal to the material stellite 6

|

Material : |

JX –Grade 3 and 20 |

|

Process : |

Powder Metallurgy , it is short for PM |

|

Hardness: |

53-59HRC |

|

Density : |

8.6-8.8 g/cm ³ |

|

Size : |

Diameter 11-60 mm

|

|

Properties : |

Wear and corrosion resistance, high temperature resistance |

|

Application : |

Oil well pump components , wear and corrosion resistance parts |

|

Instructions : |

Drawing made upon cutomers request |

|

Usage : |

one balls with one valve |

|

Tolerance control : |

turning or grinding surface , tolerance upon drawing |

|

Production lead time |

Samples 10 days , normal order 30 days |

|

Production capacity : |

40,000pcs one month. |

|

Package : |

carton or wooden case , pallet for export |

Cobalt Chromium Tungsten Alloy Valve Seats Chemical compositions and properties (%)

|

Brand |

C |

Mn |

Si |

Cr |

Ni |

Mo |

W |

Co |

Fe |

P |

S |

Density (g/cm3) |

Hardness (HRC) |

|

Stellite 3 |

2.0-2.7 |

1.0 |

1.0 |

29-33 |

3.0 |

|

11-14 |

Bal. |

3.0 |

≤0.03 |

≤0.03 |

8.55 |

51-55 |

|

Stellite 20 |

2.2-3.0 |

|

2.0 |

30-34 |

3.0 |

1.0 |

14-18 |

Bal. |

3.0 |

≤0.05 |

≤0.05 |

8.65 |

53-59 |

Dimensions of our Cobalt Chromium Tungsten Alloy Valve Seats

API Valve Seat Standard

|

No. |

Specifications |

Dimensions OD/ID×H (in) |

Weight (g/pc) |

|

1 |

VII-106 |

0.793/0.460×0.500 |

22.81 |

|

2 |

VII-125 |

0.918/0.550×0.500 |

29.55 |

|

3 |

VII-150 |

1.168/0.670×0.500 |

49.53 |

|

4 |

VII-175 |

1.388/0.825×0.500 |

68.13 |

|

5 |

VII-200 |

1.478/0.960×0.500 |

69.05 |

|

6 |

VII-225 |

1.720/1.060×0.500 |

100.34 |

|

7 |

VII-250 |

2.010/1.310×0.500 |

127.04 |

|

8 |

VII-375-1 |

3.072/1.700×0.750 |

536.94 |

|

9 |

VII-375-2 |

3.072/1.880×0.750 |

484.12 |

Please leave your information to get the latest quotation and product catalogue!