Product Description

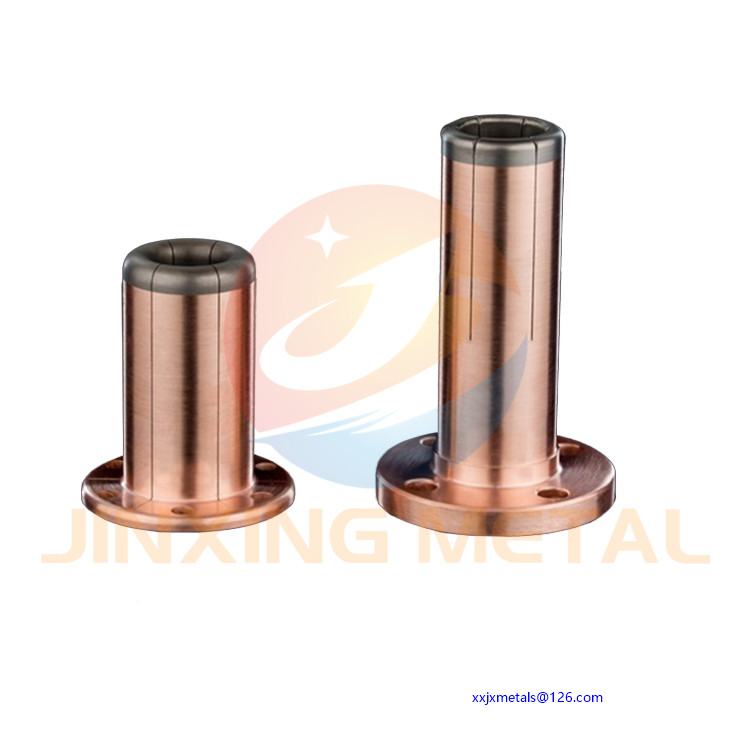

Copper Tungsten Tube

Tungsten Copper has the ability to provide stable cutting in carbide and other refractory metals. Tungsten copper tube is most widely used to machine tungsten carbide when fine surface finishes are required. Thin sheets, small diameter rods, and Tube are all 60/40 (60% Tungsten, 40% copper) composition. Plates, round bars and square bars are 70/30 (70% tungsten, 30% copper) composition.

Copper Tungsten Tubes/Pipes

Tungsten Copper Tube (WCu)

2) Class: Round tube and Square tube

3) Specifications:

OD:5.0mm to 300 mm; Length: max 300 mm; Wall thickness: min 0.3 mm

Wall Thickness: 0.3-20mm*10-120mm*10-120mm; Length: 300mm below

All can be produced as the requirements of customers.

|

Code No. |

Chemical Composition % |

Mechanical properties |

||||||

|

Cu |

Impurity |

W |

Density |

Hardness |

RES |

Conductivity |

TRS/ Mpa |

|

|

W50Cu50 |

50 + 2.0 |

0.5 |

Balance |

11.85 |

115 |

3.2 |

54 |

|

|

W55Cu45 |

45 + 2.0 |

0.5 |

Balance |

12.3 |

125 |

3.5 |

49 |

|

|

W60Cu40 |

40 + 2.0 |

0.5 |

Balance |

12.75 |

140 |

3.7 |

47 |

|

|

W65Cu35 |

35 + 2.0 |

0.5 |

Balance |

13.3 |

155 |

3.9 |

44 |

|

|

W70Cu30 |

30 + 2.0 |

0.5 |

Balance |

13.8 |

175 |

4.1 |

42 |

790 |

|

W75Cu25 |

25 + 2.0 |

0.5 |

Balance |

14.5 |

195 |

4.5 |

38 |

885 |

|

W80Cu20 |

20 + 2.0 |

0.5 |

Balance |

15.15 |

220 |

5 |

34 |

980 |

|

W85Cu15 |

15 + 2.0 |

0.5 |

Balance |

15.9 |

240 |

5.7 |

30 |

1080 |

|

W90Cu10 |

10 + 2.0 |

0.5 |

Balance |

16.75 |

260 |

6.5 |

27 |

1160 |

Copper Tungsten Tube Advantages

We specialize in manufacturing high quality copper tungsten tubes of various sizes and wall thicknesses. Using state-of-the-art technologies, We produces products that last long, are durable and highly efficient. No matter what requirement is, we are capable of manufacturing copper tungsten tubes as per your exact specification-be it 70WCu, 75WCu, 80WCu, 85WCu, 90WCu or 93WCu.

Copper tungsten Tube (WCu80) has characteristics of tungsten and copper both, with good high-temperature endurance, reliable electronic arc burning & corrosion endurance, high specific gravity and strong intensity. Copper tungsten Tube can be used in radiator of electronic components, electronic emission materials, welding electrodes, home appliance and spare parts for clocks.

Applications for Copper Tungsten Tube

Copper tungsten Tube is widely used in the fields of machinery, electric power. Copper tungsten Tube can also be used in electron, metallurgy, aviation and spaceflight. We use HIP molding plant – high temperature sintered tungsten matrix – copper-impregnated impregnation technology that, can produce copper tube tungsten for 6-50% of the various pieces of large or profiled copper tungsten alloy material we produced has characteristics of high-density, high thermal conductivity, high strength and hardness, low resistivity, low thermal expansion coefficient and easy machining etc, and copper tungsten tube has excellent performance in areas of the burning arc of resistance, anti-welded and corrosion resistance. We can provide all kinds of copper tungsten Tube as per your requirements.

Please leave your information to get the latest quotation and product catalogue!