Product Description

High Purity 99.95% Moly Rod

High Purity 99.95% Moly Rod can withstand extreme temperatures and maintain its strength and rigidity at high temperatures. The melting point of molybdenum is 2623°C. It has good thermal conductivity and low thermal expansion. Molybdenum rods are manufactured as pieces of any length or cut to the length required by the customer. Molybdenum has excellent corrosion resistance similar to tungsten

High Purity 99.95% Moly Rod application:

1. Suitable for the production of ion implanted parts.

2. Used to produce heating elements and refractory parts in high-temperature furnaces

3Used to produce electric light source components and electric vacuum components.

4. Electrodes used in the rare earth metal industry.

5. Used in glass and glass fiber industry, long service life in molten glass at 1300℃.

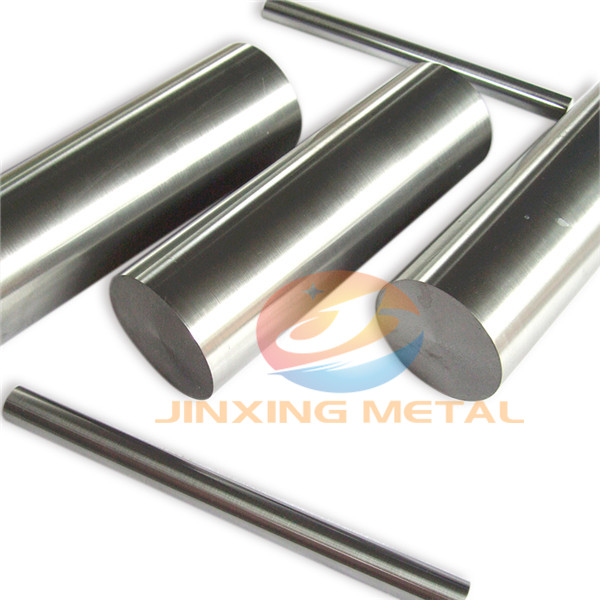

Moly Rod Picture:

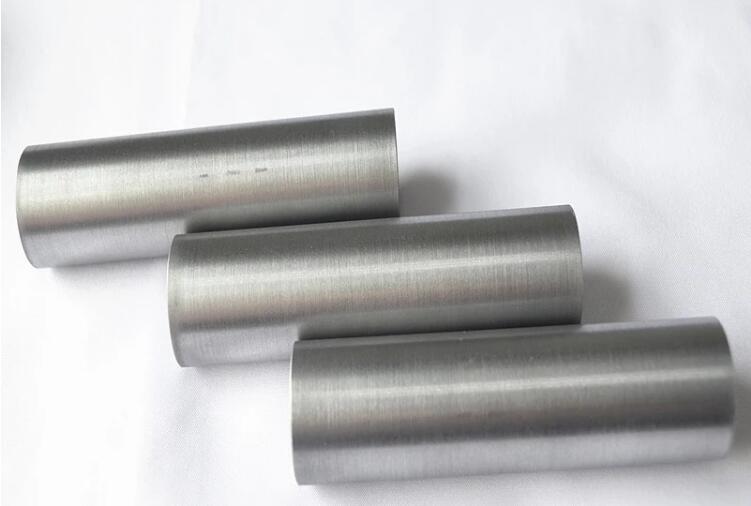

Moly Rod Exterior:

There are forged molybdenum rods and polished molybdenum rods; oxide film and slight forging hammer marks are allowed on the surface of forged molybdenum rods; the surface of polished molybdenum rods has metallic luster without obvious oxidation. There are no defects such as delamination, cracks, burrs, and vertical cracks on the two surfaces.

Surface finish:

Black-the surface is "compressed" or "stretched"; a layer of processing lubricant and oxide is retained.

Cleaning-The surface is chemically cleaned to remove all lubricants and oxides.

Ground-The surface is a centerless ground to remove all coatings and achieve precise diameter control.

Please leave your information to get the latest quotation and product catalogue!