Product Description

High Purity Cobalt Bar Description

We first purify the high-quality cobalt material, and then through mold casting, press forming, machining quality inspection, and other processing. We have more than 20 years of professional experience in the production of non-ferrous metal products and can accept customer's customized requirements.

Features

- Good processing performance, high hardness, strong dimensional stability

- High melting point, high-temperature resistance, strong oxidation resistance

- High conductivity, strong current-carrying ability, good current shock resistance

- High magnetic, anti-radiation ability, wear resistance, durable

Application

High Purity Cobalt Bars can be widely used in aerospace, mechanical manufacturing, oil and gas exploration, electronic engineering, magnetic materials, and medical devices.

- Metallurgical industry : commonly used in the manufacture of mechanical parts, alloy materials (heat-resistant alloy, hard alloy, anti-corrosion alloy, and magnetic alloy), turbine blades, tool materials, and thermal barrier coating materials

- Aerospace : used in the manufacture of high-temperature components of aircraft engines, such as afterburners, turbines, and jet chamber insulation

- Geological exploration : widely used as cementing material and other corrosion-resistant parts for oil and natural gas wellheads

- Cutting tools : Cobalt base alloy rods are also used in the manufacture of cutting tools, such as drills, milling cutters, etc. Their high hardness and wear resistance allow these tools to extend their service life

High Purity Cobalt Bar Specifications:

|

Material |

Cobalt or Cobalt Alloy |

|

Purity |

99.95%-99.99% |

|

Density |

8.9g/cm3 |

|

Diameter |

6-120mm |

|

Length |

50-2500mm |

|

Surface |

Polished, Chemically Cleaned, Grinding |

|

Delivery time |

20 days |

|

Tensile Strength |

500-600 Mpa |

|

Standard |

DIN, ANSI, ASTM, AMS, GB |

|

Certification |

ISO9001 |

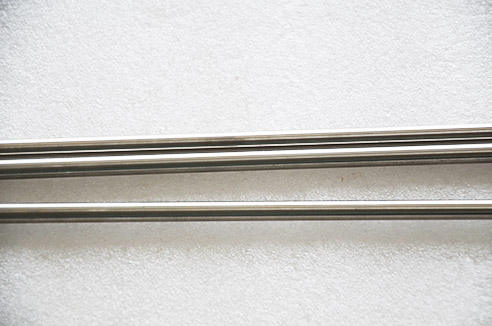

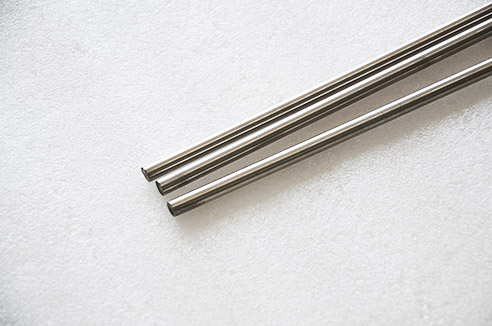

High Purity Cobalt Bar Pictures

Please leave your information to get the latest quotation and product catalogue!