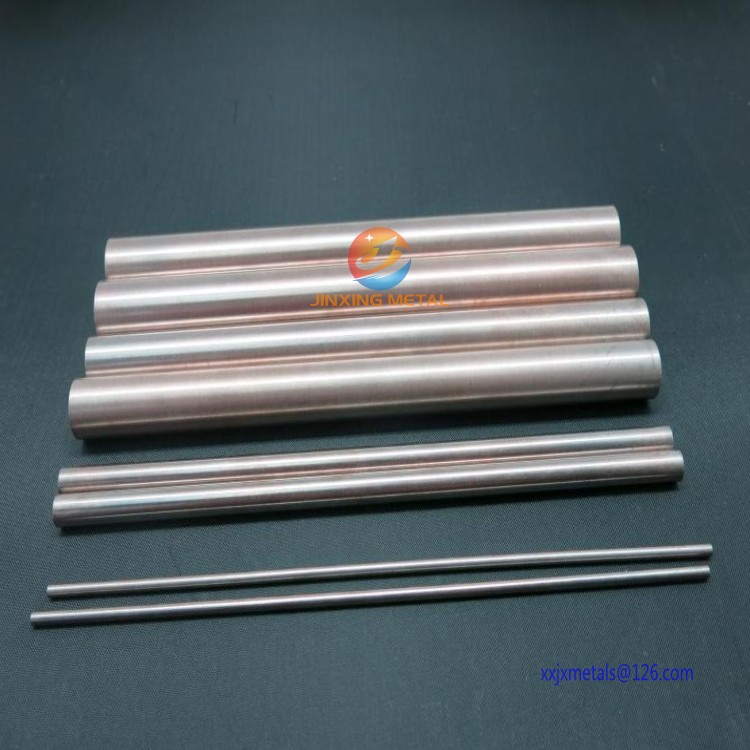

Product Description

Molybdenum Copper Rod Feature :a kind of alloy that replaces copper and tungsten copper. It adopts high-quality molybdenum powder and oxygen-free copper powder, applies isostatic pressing (high-temperature sintering-permeating copper), which has fine structure, good arc breaking performance, good electrical conductivity, good thermal conductivity and small thermal expansion., high strength, high specific gravity, high temperature resistance, arc ablation resistance, good electrical and electrical properties, and good processing performance. Molybdenum copper rods, similar to tungsten-copper alloys, also have compositional tunability for adjustable thermal conductivity and thermal expansion coefficient.

Molybdenum Copper Rod is suitable for the manufacture of military high-power microelectronic devices as heat sink sealing materials and molybdenum copper rods for sealing and structural materials of aluminum oxide ceramics. It is also suitable for manufacturing high thermal conductivity expansion sealing heat in civil high-power microelectronic devices as the use of molybdenum copper rods.

advantages

1. 40% higher than similar tungsten copper alloy

2. Maximum thermal conductivity

3. Thermal and mechanical properties

4. Thermal expansion

5. No need for expensive molds

6. High precision parts processing

7. Plating and metal are available

8. Sealed

Molybdenum Copper Rod Application

§ vacuum contact

§ conductive heat element

§ instrument element

§ high-temperature components

§ electrode tip, edm electrode

Please leave your information to get the latest quotation and product catalogue!