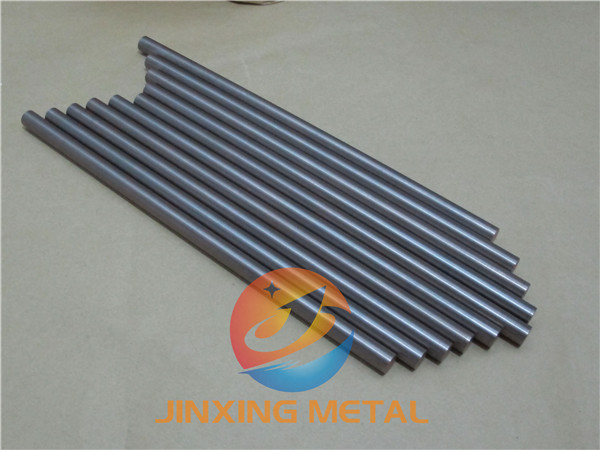

Product Description

Tungsten Wire Details

Silver and tungsten in the liquid or solid matter can not miscible. Preparation of silver tungsten alloy powder metallurgy method can only be made using sintered materials can also be used extrusion method. Features silver tungsten material is close to the high hardness, resistance to arc erosion, anti-adhesion and anti-welding capability. Manufactured by powder metallurgy method. More than 60% tungsten alloy multi-use soaked production. Tungsten-silver alloy is generally used as low-voltage power switch, crane switch, engine switch, high current switching contacts of the pre-and heavy-duty relays, air circuit breakers. Plus cobalt tungsten can improve the wettability of silver, to reduce the contact resistance.

Tungsten silver alloy material is widely used in high temperature, high pressure switch with electrical alloy, EDM electrodes, microelectronics materials, parts and components as widely used in aerospace, aviation, electronics, electric power, metallurgy, machinery, sports equipment and other industries .

Tungsten Silver No.:AgW30 AgW40 AgW50 AgW55 AgW60 AgW65 AgW70 AgW75 AgW80 AgW85

Technical parameters:

|

Product Name |

Symbol |

Silver |

Impurities |

Tungsten |

Density g/cm3 |

Conductivity IACS% |

Hardness HB≥ |

Flexural strength |

|

Silver Tungsten30 |

AgW30 |

70±1.5 |

0.5 |

Margin |

11. 75 |

|

75 |

75 |

|

Silver Tungsten40 |

AgW40 |

60±1.5 |

0.5 |

Margin |

12.4 |

|

66 |

85 |

|

Silver Tungsten50 |

AgW50 |

50±2.0 |

0.5 |

Margin |

13.15 |

|

57 |

105 |

|

Silver Tungsten55 |

AgW55 |

45±2.0 |

0.5 |

Margin |

13.55 |

|

54 |

115 |

|

Silver Tungsten60 |

AgW60 |

40±2.0 |

0.5 |

Margin |

14 |

|

51 |

125 |

|

Silver Tungsten65 |

AgW65 |

35±2.0 |

0.5 |

Margin |

14.5 |

|

48 |

135 |

|

Silver Tungsten70 |

AgW70 |

30±2.0 |

0.5 |

Margin |

14.9 |

45 |

150 |

657 |

|

Silver Tungsten75 |

AgW75 |

25±2.0 |

0.5 |

Margin |

15.4 |

41 |

165 |

686 |

|

Silver Tungsten80 |

AgW80 |

20±2.0 |

0.5 |

Margin |

16.1 |

37 |

180 |

726 |

Please leave your information to get the latest quotation and product catalogue!