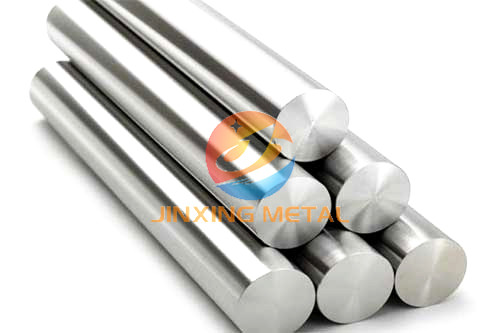

Product Description

- Product Name: Titanium Bar

- Material: Titanium

- Nominal Thickness: 0.3mm~60mm

- Type: TA1-TA4, TA8-TA10, TA15-TA18, Gr1~Gr5, Gr7, Gr9, Gr11, Gr12, TI-6AL-4V Eli, Ti-6Al-7Nb

- Standard: ASTM B348, ASME SB348, ASTMF67, ASTMF136, ISO-5832-2, ISO-5832-3, AMS4928, MIL-T-9047, JIS, GB/T2965-2007, GB/T13810-2007

- Shape: Round bar, Square /flat bar, Hexagonal bar, Rectangle bar

- Finish: Sand blasted, Pickled, Machined (Turned or center-less grinded)

- Condition: Cold rolled(Y)~Hot rolled(R)~Annealed (M)~Solid Status

- Application: Industrial, medical, aviation, military, salt-making, petrochemical, metallurgy, electronics, etc.

- Chemical Compositions:

|

|

N |

C |

H |

Fe |

O |

Al |

V |

Pa |

Mo |

Ni |

Ti |

|

Gr 1 |

0.03 |

0.08 |

0.015 |

0.20 |

0.18 |

/ |

/ |

/ |

/ |

/ |

bal |

|

Gr 2 |

0.03 |

0.08 |

0.015 |

0.30 |

0.25 |

/ |

/ |

/ |

/ |

/ |

bal |

|

Gr 3 |

0.05 |

0.08 |

0.015 |

0.30 |

0.35 |

/ |

/ |

/ |

/ |

/ |

bal |

|

Gr 4 |

0.05 |

0.08 |

0.015 |

0.50 |

0.40 |

/ |

/ |

/ |

/ |

/ |

bal |

|

Gr 5 |

0.05 |

0.08 |

0.015 |

0.40 |

0.20 |

5.5~6.75 |

3.5~4.5 |

/ |

/ |

/ |

bal |

|

Gr 7 |

0.03 |

0.08 |

0.015 |

0.30 |

0.25 |

/ |

/ |

0.12~0.25 |

/ |

/ |

bal |

|

Gr 9 |

0.03 |

0.08 |

0.015 |

0.25 |

0.15 |

2.5~3.5 |

2.0~3.0 |

/ |

/ |

/ |

bal |

|

Gr12 |

0.03 |

0.08 |

0.015 |

0.30 |

0.25 |

/ |

/ |

/ |

0.2~0.4 |

0.6~0.9 |

bal |

- Allowable Deviation:

|

Diameter or Thickness |

Allowable Deviation |

||

|

|

Hot forged rod |

Hot roll rod |

Cold rolled rod |

|

>7~15 |

±1.0 |

+0.6, -0.5 |

±0.3 |

|

>15~25 |

±1.2 |

+0.7, -0.5 |

±0.4 |

|

>25~40 |

±1.5 |

+1.0, -0.5 |

±0.5 |

|

>40~60 |

±2.0 |

+1.2, -0.8 |

±0.6 |

|

>60~90 |

±2.5 |

+1.5, -1.0 |

±0.8 |

|

>90~120 |

±3.0 |

+2.0, -1.0 |

±1.0 |

|

>120~160 |

±4.0 |

—— |

±1.5 |

|

>160~200 |

±5.0 |

—— |

±1.8 |

|

>200~230 |

±6.0 |

—— |

±2.0 |

|

Deviation of length(mm): L<500, +5max; L>500, +10max |

|||

- Degree of Curvature:

|

Processing method |

Diameter or Thickness (mm) |

Degree of Curvature (mm/m) |

|

Hot processing |

< 35 |

6 |

|

Hot processing |

≥35 |

10 |

|

Hot processed, polished & cold processed round, square rod |

< 35 |

4 |

|

|

≥35 |

5 |

“Advanced Material Changes Our Life!”

Our Services

Quality is the soul of our company!

We track every production process, inspect every single part, and record every step, for we know that "Quality first" is always our principle.

1.Provide third-part inspection reports.

2.Visual inspection to check surface quality, ensuring without flaw, black dot and any other defects.

3.Ultrasonic Flaw Detection making sure there are no defects inside.

4.Chemical Compositionmaking sure all chemical components can satisfy customer's demands

5.Mechanical Property testingmaking sure all titanium bars have satisfying mechanical features before delivery.

6.ISO Quality Management System-SGS test

Please leave your information to get the latest quotation and product catalogue!