Product Description

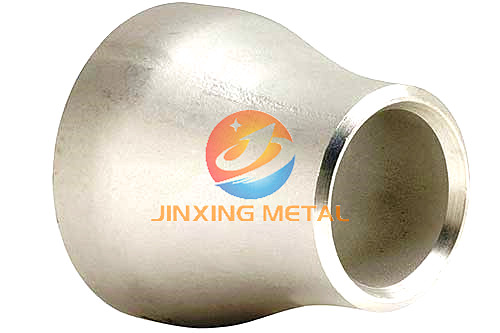

Titanium Reducer Description£º

Titanium fittings are mainly used for the material flow (acid, alkali, salt corrosion medium liquid) between equipments in the chemical plant, to connect the titanium equipment pipes. There are two kinds of manufacturing process of titanium fittings. The DN140 above titanium fittings are mainly produced by extrusion forming and welding technology of titanium sheet, under DN140 titanium fittings mainly produced with the seamless tube extrusion molding process. In addition to the standard size of the titanium fittings, we also produce non-standard titanium fittings according to customer drawings.

Our high precision mould guaranteed the precision of extrusion process, and our workers are holding welding certificates of pressure vessel which guarantees the quality of welding kept a high level.

Titanium Reducer type£º

ASME B16.9 Factory –Made Wrought Buttwelding FittingsASME B16.25 Buttwelding EndsASME B36.10 Welded and Seamless Wrought Steet PipeASME B36.19 Stainless Steel Pipe

ASME B31.3 Process Piping

ASME B16.5 Pipe Flanges and Flanges [NPS1/2 Through NPS24] Metric/Inch Standard £¨NPS1/2~NPS24

ASME B16 .47 Large Diameter Steel Flanges NPS 26 Through NPS 60 Metric/Inch Standard

ASTM B861 Standard Specification for Titanium and Titanium Alloy Seamless Pipe

ASTM B862 Specification for titanium and Titanium and Alloy Welding Pipe

ASTM B381 Standard Specification for Titanium and Titanium Alloy Seamless Forgings

MSS SP-97 Integrally Reinforced Forged Branch Outlet Fittings-Socket Welding£¬Threaded and Buttwelding Ends

MSS SP-43 Wrought Stainless Steel Butt¬—Welding Fittings

AWS A5.16/A5.16M-2007 Specification for titanium and Titanium and Alloy Welding Electrodes and Rods

GB/T27684-2011

GB/T20623-2009

HG/T3651-1999

HG/T20592-2009

GB/T12459-2005

GB/T13401-2005

GB/T19326-2003

Application:

Titanium with low density , high specific strength and strong corrosion resistance , has become a new engineering material widely used in aviation , aerospace ,navigation,petroleum,chemicalindustry,metallurgy ,electroplating , vacuum coating ,medical industry,sports and other industries.

All titanium product by our company are made of fine titanium material. After strict quality control in ingot casting ,forging and maching processes, they can completely meeting customer's various and specific requirements.

Our Services

Quality is the soul of our company!

We track every production process, inspect every single part, and record every step, for we know that "Quality first" is always our principle.

1.Provide third-part inspection reports.

2.Visual inspection to check surface quality, ensuring without flaw, black dot and any other defects.

3.Ultrasonic Flaw Detection making sure there are no defects inside.

4.Chemical Compositionmaking sure all chemical components can satisfy customer's demands.

5.Mechanical Property testingmaking sure all titanium bars have satisfying mechanical features before delivery.

6.ISO Quality Management System-SGS test.

Please leave your information to get the latest quotation and product catalogue!