Product Description

Tungsten Carbide Insert Carbide Cutting Tool Description

Tungsten Carbide Insert Carbide Cutting Tool is mainly made of tungsten carbide particles and metal binder (usually cobalt) after powder metallurgy processing, which can resist deformation and chips under extreme stress and high-temperature conditions, and is widely used in automotive, aerospace, and medical equipment. Industrial sectors such as construction and mining. Tungsten Carbide Insert is an essential tool for any hard material that needs to be precisely cut, formed, and drilled, such as steel, cast iron, stainless steel, and non-ferrous metals, and is often used in drilling and boring operations in the construction and mining industries. They can drill through rock, granite, and concrete with high precision and speed.

Tungsten Carbide Insert Carbide Cutting Tool Features

1. Tough and durable, with high wear resistance, heat resistance and fragmentation resistance. This toughness allows them to hold a longer cutting edge than other materials, which improves the efficiency and precision of machining operations.

2. Excellent thermal stability, which means they maintain their cutting properties even at high temperatures.

3. Their hardness and strength allow them to cut even the most difficult materials to process, such as superalloys, stainless steel and hardened steel.The

Tungsten Carbide Insert Carbide Cutting Tool Specification

|

Grade |

YG6,YG8,YG10,K10,K20,K30 |

|

Purity |

WC:85%-97%,Co:3%-15% |

|

Technique |

Pressing, Hot-rolled, Welding, Punching, Forging, Sintered |

|

Shape |

Triangular, Quadrilateral, Pentagon, Circular and Diamond |

|

Size |

Customized |

|

Density |

13.5g/cm3-15.1g/cm3 |

|

Hardness |

≥89-93HRA |

|

Delivery Time |

20 days |

|

Surface |

Mirror Polished, Alkaline Cleaning |

|

Certification |

ISO 9001 |

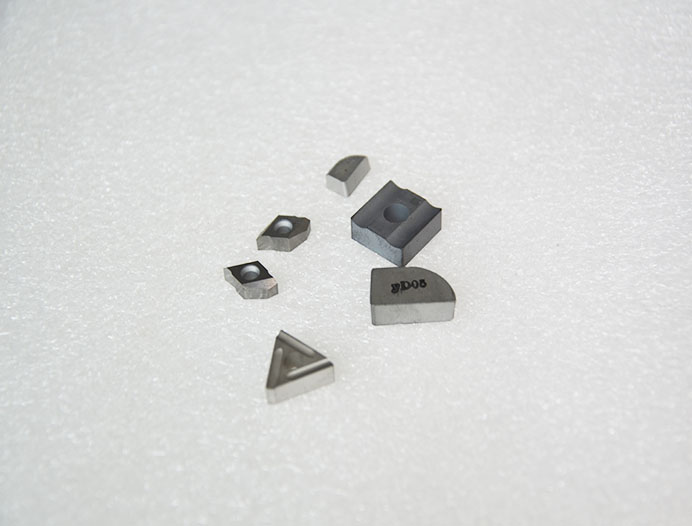

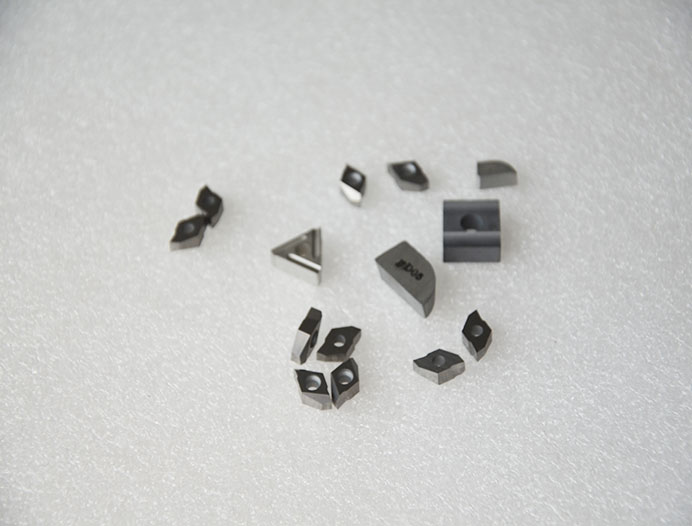

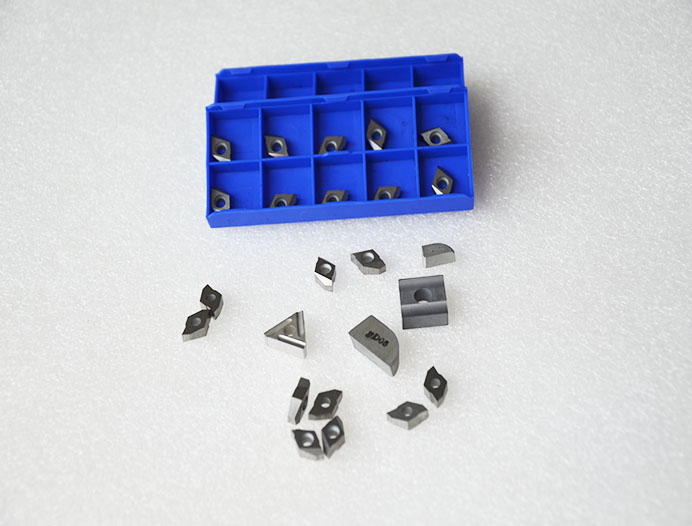

Tungsten Carbide Insert Carbide Cutting Tool Picture

Please leave your information to get the latest quotation and product catalogue!