Product Description

Tungsten-copper electrode is a kind of composite material made by static pressing, high-temperature sintering, and smelting refined copper by taking advantage of the plasticity and high conductivity of high-purity tungsten metal powder and high-purity copper powder.

Tungsten Copper Alloy Welding Electrode Application:

* Heat shields and thermal bodies for the production of w-boats, high temperature furnaces

* For the production of electric light source parts, electric vacuum components;

Commonly used copper-tungsten alloys contain 10-50wt.% copper, and most of the rest are tungsten. The typical properties of an alloy depend on its composition.

(5) Alloys with less copper content have higher density, hardness and resistivity. When the copper content is 10%, the density of CuW90 alloy is 16.75 g/cm3, and the density of CuW50 alloy is 11.85 g/cm3. CuW90 has higher hardness and resistivity, 260 HB kgf/mm2 and 6.5 µΩ, respectively. than CuW 50 cm.

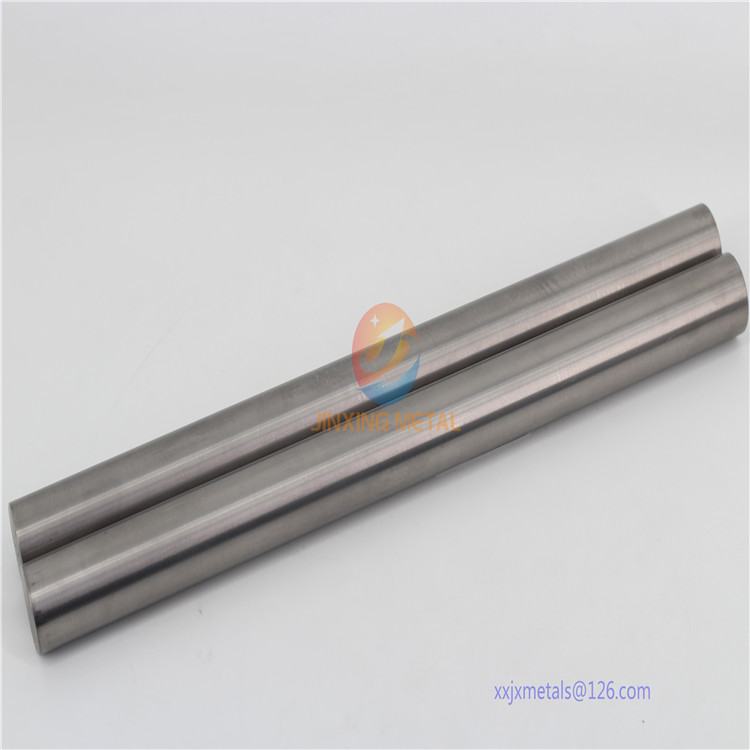

Tungsten Copper Alloy Welding Electrode Picture:

Tungsten Copper Alloy Welding Electrode Compositions

| Composition wt.% | Density g/cm3 | Hardness HB Kgf/mm2 | Resistivity | IACS % | Bending strength Mpa |

|---|---|---|---|---|---|

| W50/Cu50 | 11.85 | 115 | 3.2 | 54 | — |

| W55/Cu45 | 12.30 | 125 | 3.5 | 49 | — |

| W60/Cu40 | 12.75 | 140 | 3.7 | 47 | — |

| W65/Cu35 | 13.30 | 155 | 3.9 | 44 | — |

| W70/Cu30 | 13.80 | 175 | 4.1 | 42 | 790 |

| W75/Cu25 | 14.5 | 195 | 4.5 | 38 | 885 |

| W80/Cu20 | 15.15 | 220 | 5.0 | 34 | 980 |

| W85/Cu15 | 15.90 | 240 | 5.7 | 30 | 1080 |

| W90/Cu10 | 16.75 | 260 | 6.5 | 27 | 1160 |

Please leave your information to get the latest quotation and product catalogue!