Product Description

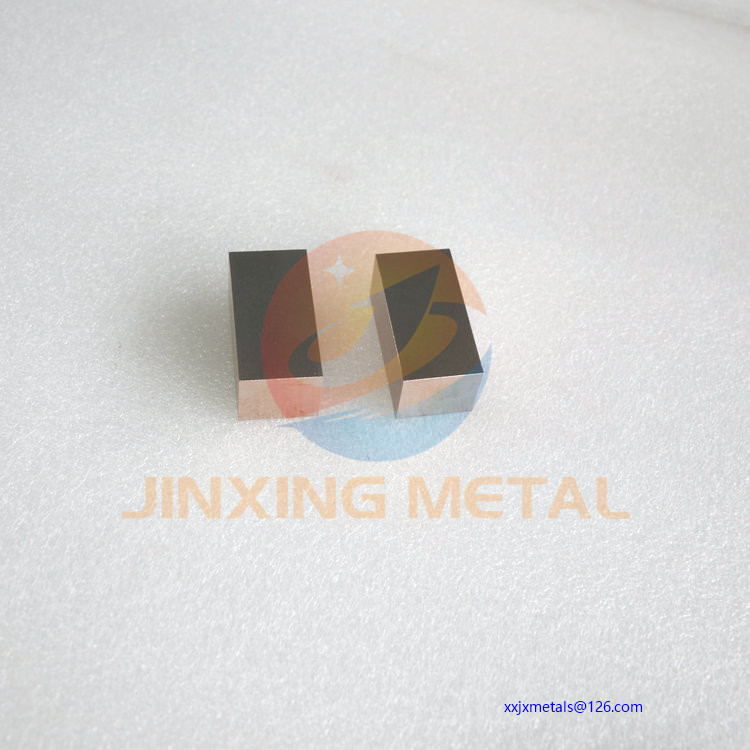

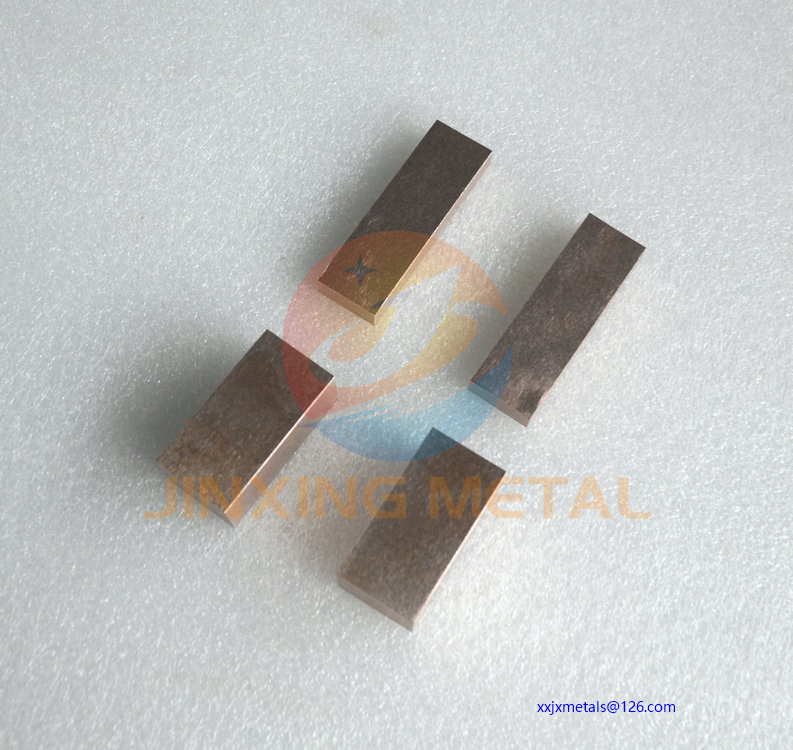

Tungsten-Copper Heat Sink

They are composites of tungsten and copper. By adjusting the content of tungsten, we can have its coefficient of thermal expansion (CTE) designed to match those of materials such as ceramics (Al2O3, BeO), semiconductors (Si), and metals (Kovar), etc.

Our products are widely used in applications such as optoelectronics packages, Microwave Packages, C Packages, Laser Submounts, etc.

Tungsten Copper Heat Sink Advantages

High thermal conductivity

Excellent hermeticity

Excellent flatness, surface finish, and size control

Semi-finished or finished (Ni/Au plated) products available Tungsten Copper Heat Sink

Chinatungsten offers special high conductivity and low thermal expansion metals and ceramic materials. All materials are available as finished components and in sheet form. Metals are available either as composites or as laminated sheets.

Cu/MoCu sheets have very high in plane conductivity provide by layers of copper and low thermal expansion provided by the inner layer of molybdenum. These laminated sheets have the ability to spread the heat from a concentrated heat source and then dissipate the heat through the layers. They also:

· Offer an economical solution to many applications

· Will not delaminate and can resist repeated 850° C cycles

· Available in several standard ratios and many thicknesses for tailored TE machining

· Are lower weight than WCu composite materials

· Are available in larger and thinner sheet size

· Utilize copper that is easily plated

· Can be machined by EDM

WCu composites are made by infiltrating, under vacuum, uniform controlled porous blocks of tungsten with molten copper. This results in a material with an interconnected copper matrix that has high thermal conductivity in all axis, low thermal expansion, and good electrical conductivity, Copper content can range between 10% and 25%.

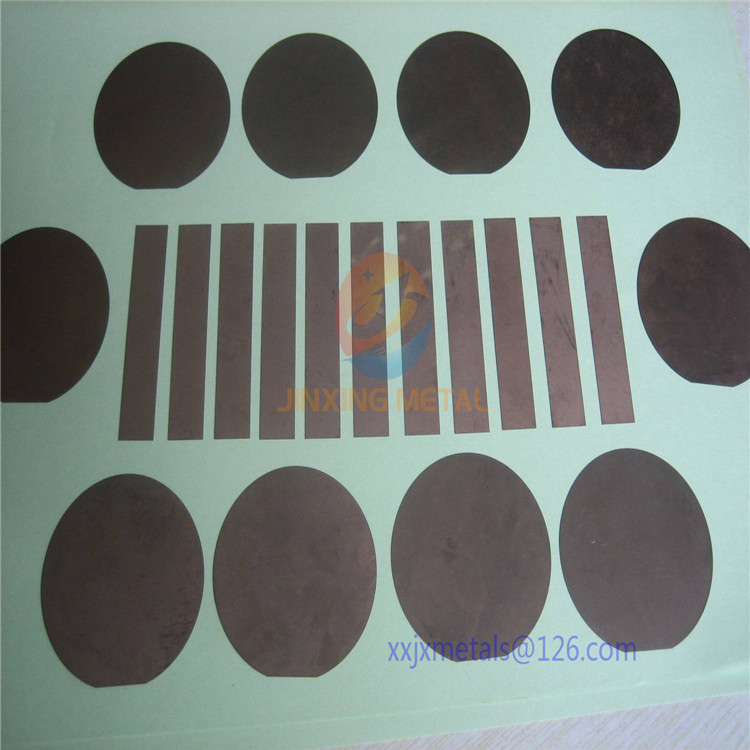

MoCu alloys are made by sintering molybdenum and copper together. This results in a tungsten copper heat sink of lower density, low CTE and excellent thermal conductivity. Other features include:

· Sheets can be stamped when moly is less than 70%

· Non magnetic

· Relatively low density

· Can be gold or nickel plated

Tungsten/Copper – Moly/Copper – Cu/Mo/Cu Heat Sink Meterials

|

Type |

Materials |

Densityg/cm3 |

Thermal ConductivityW/m·k |

CTE, ppm/ºk20-100℃ |

|

Composite |

W90Cu |

16.6-17.0 |

180-190 |

5.6-6.3 |

|

W85Cu |

16.2-16.6 |

190-200 |

6.3-7.0 |

|

|

W80Cu |

15.4-15.8 |

200-220 |

7.8-8.5 |

|

|

W75Cu |

14.8-15.2 |

220-240 |

9.5-10.2 |

|

|

Mo70Cu |

9.6-9.8 |

190-200 |

7.8-8.4 |

|

|

Mo60Cu |

9.5-9.7 |

200-220 |

9.0-9.6 |

|

|

Mo50Cu |

9.3-9.5 |

220-250 |

10.1-10.7 |

|

|

Copper Metal Laminate |

1:1:1Cu/Mo/Cu |

9.27-9.47 |

300-310(x-y)220-230(z) |

9.6-10.0 |

|

1:2:1Cu/Mo/Cu |

9.48-9.68 |

270-280(x-y)200-210(z) |

8.5-8.9 |

|

|

1:3:1Cu/Mo/Cu |

9.6-9.8 |

240-250(x-y)180-190(z) |

7.7-8.1 |

|

|

1:4:1Cu/Mo/Cu |

9.7-9.9 |

210-220(x-y)170-180(z) |

6.8-7.2 |

|

|

1:5:1Cu/Mo/Cu |

9.74-9.94 |

195-200(x-y)165-170(z) |

6.2-6.6 |

|

|

13:74:13Cu/Mo/Cu |

9.78-9.98 |

190-200(x-y)160-170(z) |

5.7-6.1 |

|

|

1:4:1Cu/Mo70/Cu |

9.46 |

210-220(x-y)170-180(z) |

7.2 |

Tungsten Copper Heat Sink picture

Please leave your information to get the latest quotation and product catalogue!