Products

-

A crucible is a container that can withstand very high temperatures and is used for metal, glass, and pigment production as well as a number of modern laboratory processes. While crucibles historically were usually made from clay, they can be made from any material that withstands temperatures high enough to melt or otherwise alter its contents

-

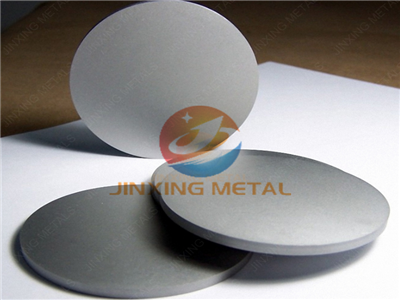

JINXING METAL offers a complete line of sputtering targets ranging from commercial grade to highest purity, zone refined Ultra-Pure grade. These materials can be fabricated to fit all commercially available systems or to specific dimensions required for your particular applications. A number of metallurgical techniques are employed in PVD material fabrication.

-

Molybdenum-Tungsten is the alloying of molybdenum with tungsten leads to better corrosion resistance against molten zinc. We produce standardized MoW alloys with 30 weight% of tungsten (MOLY B60) and 50 weight% W.

-

JINXING METAL offers a complete line of sputtering targets ranging from commercial grade to highest purity, zone refined Ultra-Pure grade. These materials can be fabricated to fit all commercially available systems or to specific dimensions required for your particular applications. A number of metallurgical techniques are employed in PVD material fabrication.

-

JINXING METAL offers a complete line of sputtering targets ranging from commercial grade to highest purity, zone refined Ultra-Pure grade. These materials can be fabricated to fit all commercially available systems or to specific dimensions required for your particular applications. A number of metallurgical techniques are employed in PVD material fabrication.

-

- high quality 4n price niobium oxide sinter

- low price ASTM B365 UNS R05252 Tantalum rod wire

- high quality 20V 47uF Capacitor SMD Tantalum capacitor Type D

- low price 99.99% purity niobium oxide manufacturer

- 0.5mm tantalum foil for industry use