The quality of the Tantalum Rod,Tantalum sputtering target,Tantalum Tube Form JINXING Matmetals

Tantalum Tantalum is a shiny, silvery metal which is soft when is pure. It is almost immune to chemical attack at temperatures below 150 C. Tantalum is virtually resistant to corrosion due to an oxide film on its surface. Applications Tantalum finds use in four areas: high-temperature applications, such as aircraft engines; electrical devices, such as capacitors; sirurgical impants and handling corrosive chemicals. It is rarely used as an alloying agent because it tends to make metals brittle. Tantalum resist corrosion and is almost impervious to chemical attack, for this reason it has been employed in chemical industry, efor heat exchanger in boilers where strong acids are vaporized. Tantalum in the environment Because tantalum oxide is very insoluble, there is almost no tantalum to be found in natural waters. Few attemps have been made to measure its level in soils, revealing a range from 0.1 to 3 ppm. Only tiny amounts of tantalum are taken by plants: the amount in vegetation rarely exceeds 5 ppb. The chief tantalum ores are tantalite, which also contains iron, manganese and niobium, and samarskite, which contains seven metals. Another ore which contains tantalum and niobium is pyrochlore. . The demand of tantalum is about 2300 tonnes a year。Read more: https://www.matmetals.com/product/tantalum-sputtering-target-2

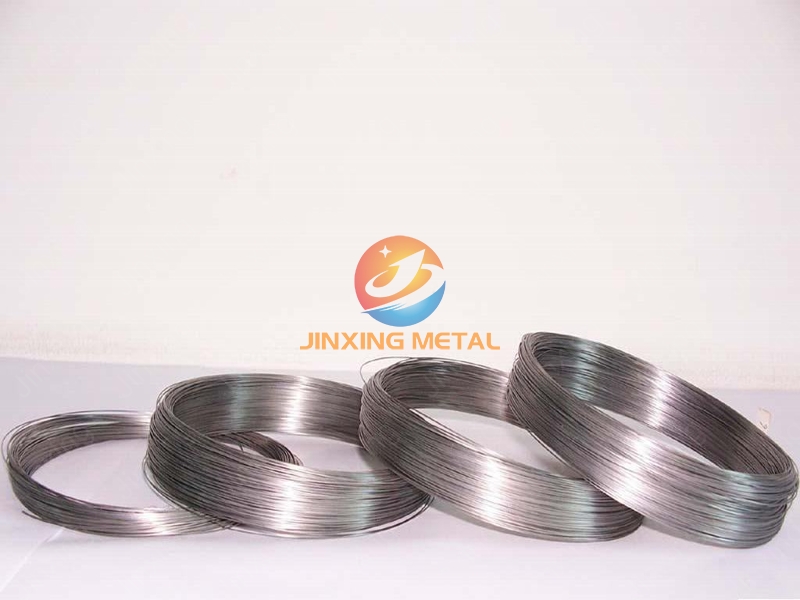

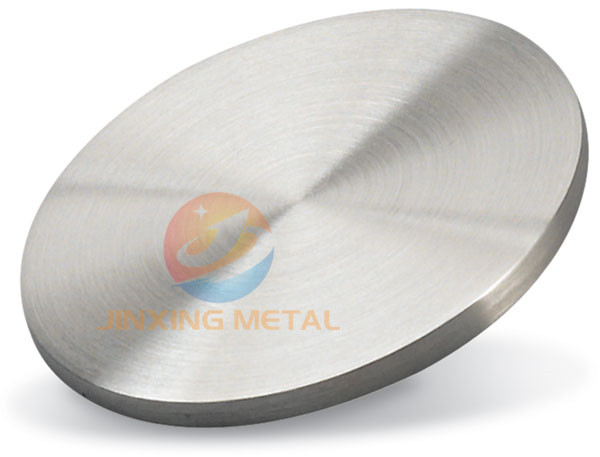

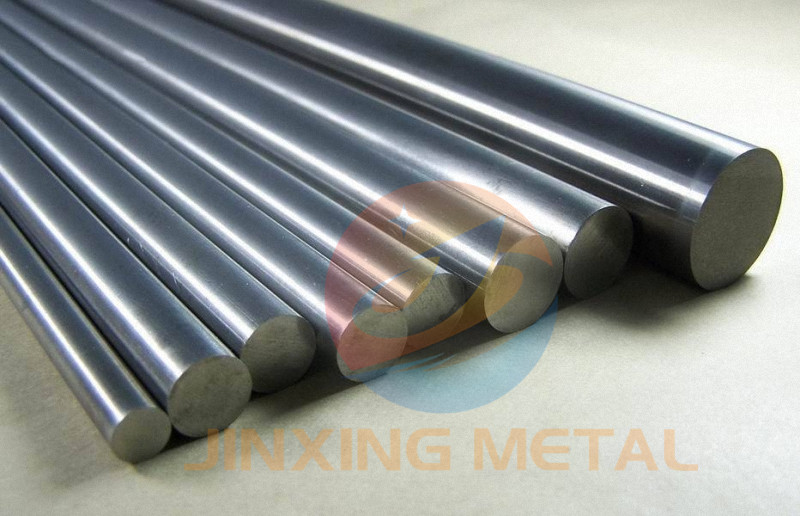

Uses Tantalum s main use is in capacitors for consumer electronics, where it faces competition from aluminum, niobium, and multi-layer ceramics. This sector used to account for >60% of demand, but is now less than half. Due to miniaturization and operating temperatures, capacitors made of tantalum remain optimum for various applications. Tantalum is also used in sputtering targets, corrosion-resistant mill products (implants), superconductors, carbides for cutting tools, chemicals for high end optics and is also frequently used as an addition in nickel-base super alloy castings for turbine blades in jet engines and industrial gas turbines (IGT). https://www.matmetals.com/product/tantalum-rod/

There's only one thing tantalum can't do: Give up.

Tantalum's corrosion resistance makes it a valuable material in a large number of chemical applications. We use our "unyielding" material, for example, to produce heat exchangers for the equipment construction sector, charge carriers for furnace construction, implants for medical technology and capacitor components for the electronics industry.

Tantalum is a sensible choice whenever high corrosion resistance is required. Even though tantalum is not one of the noble metals, it is comparable to them in terms of chemical resistance. In addition, tantalum is very easy to work at well below room temperature despite its bodycentered cubic crystal structure.

Guaranteed purity.

You can rely on our quality. We produce our tantalum products ourselves – from the metal powder right through to the finished product. As our input material, we use only the purest tantalum powder. This ensures that you benefit from a very high level of material purity.

6.Strict quality control System: Each link of the production will be strictly controlled, ensuring without one un-qualified product being out from our company.

7.Certification Report: Material Certificate ,CE, SGS, or testing report will be offered.

8. Chemical Compositions

|

Chemistry ppm |

||||||||||||

|

Designation |

Main Contents |

Impurities maximum |

||||||||||

|

Ta |

Nb |

Fe |

Si |

Ni |

W |

Mo |

Ti |

O |

C |

H |

N |

|

|

Ta1 |

Remainder |

300 |

40 |

30 |

20 |

40 |

40 |

20 |

150 |

40 |

15 |

20 |

|

Ta2 |

Remainder |

800 |

100 |

100 |

50 |

200 |

200 |

50 |

200 |

100 |

15 |

100 |

|

TaNb3 |

Remainder |

<35000 |

100 |

100 |

50 |

200 |

200 |

50 |

200 |

100 |

15 |

100 |

|

TaNb20 |

Remainder |

170000- 230000 |

100 |

100 |

50 |

200 |

200 |

50 |

200 |

100 |

15 |

100 |

|

Ta2.5W |

Remainder |

400 |

50 |

30 |

20 |

30000 |

60 |

20 |

150 |

50 |

15 |

60 |

|

Ta10W |

Remainder |

400 |

50 |

30 |

20 |

110000 |

60 |

20 |

150 |

50 |

15 |

60 |

9. Permissible variations in diameter for Tantalum rods and Tantalum wires:

|

Diameter, inch (mm) |

Tolerance <, +/-inch (mm) |

|

0.010~0.020 excl (0.254~0.508) |

< 0.0005 (0.013) |

|

0.020~0.030 excl (0.508~0.762) |

< 0.00075 (0.019) |

|

0.030~0.060 excl (0.762~1.524) |

< 0.001 (0.025) |

|

0.060~0.090 excl (1.524~2.286) |

< 0.0015 ( 0.038) |

|

0.090~0.125 excl (2.286~3.175) |

< 0.002 (0.051) |

|

0.125~0.187 excl (3.175~4.750) |

< 0.003 (0.076) |

|

0.187~0.375 excl (4.750~9.525) |

< 0.004 (0.102) |

|

0.375~0.500 excl (9.525~12.70) |

< 0.005 (0.127) |

|

0.500~0.625 excl (12.70~15.88) |

< 0.007 (0.178) |

|

0.625~0.750 excl (15.88~19.05) |

< 0.008 (0.203) |

|

0.750~1.000 excl (19.05~25.40) |

< 0.010 (0.254) |

|

1.000~1.500 excl (25.40~38.10) |

< 0.015 (0.381) |

|

1.500~2.000 excl (38.10~50.80) |

< 0.020 (0.508) |

|

2.000~2.500 excl (50.80~63.50) |

< 0.030 (0.762) |