Zirconium Zr Sputtering Targets

Zirconium Zr Sputtering Targets Description

Thin film deposition (coating) is the process of forming and depositing a thin film coating on a substrate material that can be used to change or improve certain elements of the properties of the substrate and is an important manufacturing step in the production of many optoelectronic, solid-state and medical devices and products. Zirconium Zr Sputtering Targets is mainly made of high purity zirconium metal after forging, high temperature sintering, rolling and polishing, etc. It can sputter hard, wear-resistant, corrosion-resistant and beautiful zirconium film coating on metal processing tools or electronic products, and then improve integrated circuits. Performance and service life of optical instruments or solar cells. Zirconium Zr Sputtering Targets has the characteristics of high purity, good processing performance, fast coating speed and high quality, corrosion resistance, high temperature resistance, wear resistance, long service life, etc., widely used in electronic and information industry, such as integrated circuits, information storage, liquid crystal display, laser memory, electronic control devices, etc. It can also be widely used in the field of glass coating, wear-resistant tool manufacturing, high temperature processing industry, high-end decorative supplies and other industries.

Zirconium Zr Sputtering Targets Specifications:

|

Grade |

Zr702 |

|

Purity |

99.95%-99.99% |

|

Density |

6.5g/cm3 |

|

Circular Diameter |

OD:50-300mm,ID:30-280mm |

|

Thickness |

1mm-35mm |

|

Length |

100mm-4000mm |

|

Type |

Planar,Tube,Disc,Cylinder |

|

Delivery Time |

15-20 DAYS |

|

Surface |

Polished,Alkali Cleaning,Grinding,Black Oxide,etc. |

|

Certification |

ISO9001 |

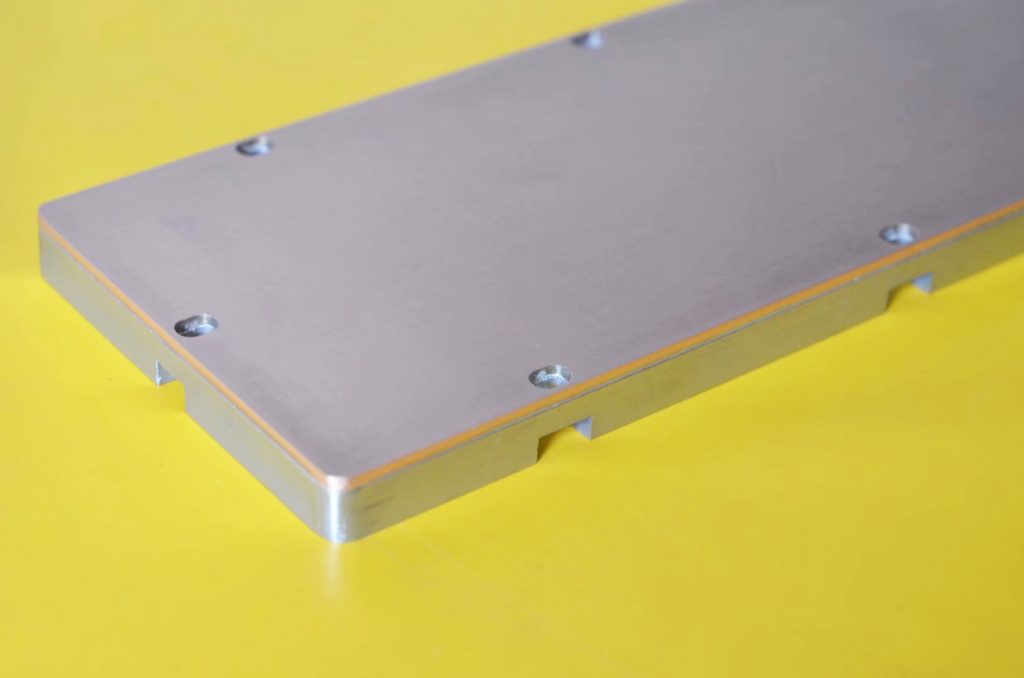

Zirconium Zr Sputtering Targets Picture